Compounding is an omnipresent process in the processing industry. Most plastics, elastomers, bitumen, paints and coatings, but also products such as chewing gum, chocolate or even aluminum would not exist without compounding technology. We combine some very different substances into materials with exceptional properties, thus helping our customers to develop new products which are fit for the future. Products used for numerous applications in the plastics, aluminum, chemicals and foodstuffs industries such as for batteries, vehicle components or in the medicinal field.

We are innovative

…so that our customers can also be innovative.

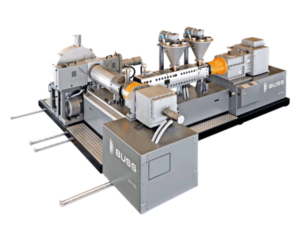

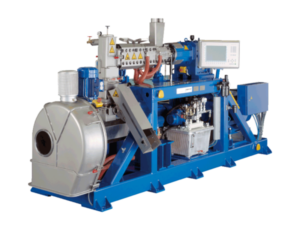

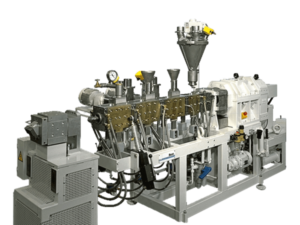

Who invented it? BUSS had its Co-Kneader Technology patented in 1945 and has continued to develop it ever since. An innovative operating principle back then, highly efficient and ergonomic, which is still applied nowadays for the demanding and highly complex processing of viscous substances. Our BUSS Co-Kneaders score with lower energy consumption, high process stability, maximum flexibility and extreme longevity. More than 3,500 compounders installed worldwide and in excess of 1,400 customers manufacture a large quantity of innovative materials as well as numerous globally renowned products prove our competence, our know-how and our promise: Excellence in Compounding day-in, day-out.

Excellence

in Compounding

This has been our claim for 80 years. Innovative solutions for new materials, combined with compounder technology know-how and experience are incorporated in all our machines. Combined with profound application know-how and line process engineering and design, we offer customers comprehensive and user-oriented advice. Our modern test centres are where we carry out research and development to find optimal solutions for improved, new and highly complex materials together with our customers.

Maximum performance with “Swissitude”

Swiss precision and thoroughness define our approach to quality management and assurance in all plant production processes. This ensures maximum product security and investment longevity for our customers. Consistent customer focus through our presence in key markets, comprehensive services, and state-of-the-art digitization packages further uphold our excellence commitment to the industry. We are a sparring partner for our customers and a forerunner in modern compounding processes “fit for the future”. Because we think outside the box and regularly address improving our technology and services even more.

Global market leader

in pioneering compounding technology. Our core competence is the analysis of the customer’s precise needs and the development of customized, product-specific solutions for producing all types of compounds. BUSS is strongest above all in meeting the highest demands on process technology and product quality. Our success is based on the capability to innovate, be flexible and to react fast, making us strong for the future and a reliable partner.

What our customers say

“BUSS is a great partner because BUSS is High Tech. Thank you for the good work.”

“BUSS is an excellent partner as its compounding delivers a very good performance. Besides, the technical support from the BUSS team is perfect. BUSS means full understanding in commercial terms.”

“Since the beginning of our partnership with BUSS, PLASCOM is successfully using BUSS compounding lines to manufacture polymer compound for wire & cables.”

“The BUSS Kneader is good compounding with high quality.”

“I express my sincere thanks for both of your continued support and understanding since the beginning of the project. Your hard work has laid a solid foundation for a long-term cooperation between NFC and BUSS. I hope that we can continue our sincere cooperation and make persistent efforts to provide technical service and maintenance work and make great efforts for NFC and BUSS on establishing a good reputation.”

“After several days of stoppage due to a break in our kneader we have restarted the production and fortunately everything is OK. The collaboration with the BUSS team was very useful and fulfilled all of our requirements. It was a very nice experience to work together “on line” with the BUSS team in Switzerland and our team in Argentina. Thank you very much for your kind and useful collaboration.”

“BUSS is a great partner as the quality of its products and the output are high, maintenance is low and spare parts are rarely required. The BUSS compounder is a very good product and disposes of features that makes it unique.”

“BUSS helped us to regain control of our machines, we have optimized the process geometry together with technicians from BUSS and we use spare parts that are fit for purpose. Machine has over 1800 hours flawless runtime in the last 9 months.”

We think globally

We act consistently and we live by Swiss value

Our roots

Engineering competence for the future

2018

COMPEO® – bereit für die Zukunft

BUSS hat das neue COMPEO Compoundier-System entwickelt, um den heutigen und zukünftigen Anforderungen der Kunststoffindustrie gerecht zu werden. Mit einem breiten Anwendungsspektrum, einem großen Betriebsfenster, einer hohen Flexibilität und Robustheit sowie einer verbesserten Prozessstabilität bei gleichzeitiger Betriebs- und Bedienersicherheit, Energieeffizienz und verringerten Betriebskosten, ist COMPEO für eine große Bandbreite von Anwendungen einsetzbar. Mehr dazu …

2013

Vorstellung der quantec® G3-Ko-Kneter-Serie für PVC

2010

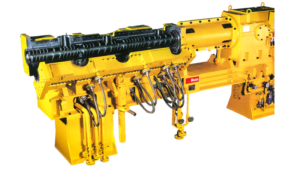

Vorstellung der KX-Ko-Kneter-Serie für Anodenmassen

2007

Vorstellung der MX-Ko-Kneter-Serie für Kabelcompounds und Black Masterbatch

2006

Übernahme der BUSS AG durch Fabrel Lotos und die BUSS-Geschäftsführung

Vorstellung der quantec® Ko-Kneter-Serie zur Kalanderbeschickung

2001

Vorstellung des quantec® Ko-Kneters für PVC

2000

BUSS, Werner&Pfleiderer und Waeschle fusionieren zur COPERION Gruppe

1995

Vorstellung der modularen MKS-Serie zur Abdeckung des gesamten Kunststoffspektrums

Vorstellung des Labor-Tischextruders PCS 30 für Pulverlacke

1994

BUSS erhält die ISO 9001/EN29001-Zertifizierung

Vorstellung der modularen PCS/TCS-Serie für Pulverlacke und Toner

1993

Gründung von Buss (Asia) Pacific Pte. Ltd. in Singapur für Vertrieb und Service

Vorstellung der elektrisch beheizten APC-Serie für technische Kunststoffe

1988

Die Georg Fischer Gruppe erwirbt die Mehrheit der BUSS-Aktien

1987

Eröffnung einer Serviceniederlassung in China

Umfirmierung des Gemeinschaftsunternehmens Buss-Condux in die Buss (America) Inc., eine hundertprozentige Tochtergesellschaft

Die BUSS LR-Serie für Lebensmittel wird mit dem internationalen IF Award für herausragendes Design ausgezeichnet

1986

Auslieferung des ersten Ko-Kneters der LR-Serie für Silikoncompounds

![]()

1983

Auslieferung des ersten elektrisch beheizten BUSS Ko-Kneters für technische Kunststoffe

1980

Auslieferung des ersten Ko-Kneters der PR-Serie mit modularem Aufbau

1975

Auslieferung des ersten kaskadenförmigen BUSS Ko-Kneters für PVC

1974

Gründung von Buss-Hamilton Ltd. in Cheadle Hulme, Großbritannien, für Vertrieb und Service

Gründung von Yashima-Buss Ltd. in Tokio, Japan, für Vertrieb und Service

1972

Gründung von Buss-Condux Inc. in Chicago, USA, für Vertrieb und Service

1969

Auslieferung des tausendsten BUSS Ko-Kneters

1968

Auslieferung des ersten BUSS Ko-Kneters für Pulverlacke