COMPEO – New configurable process zone

The fully configurable process zone of COMPEO compounders opens up completely new process engineering possibilities through the application of mixing and kneading elements with two to six rows of screw flights. The new geometries make it possible to achieve previously conflicting goals such as a high specific throughput with controllable energy input. In addition, the process window is significantly larger with COMPEO compounding machine. Throughput can be varied in a ratio of 1:6, increasing both system flexibility and user-friendliness.

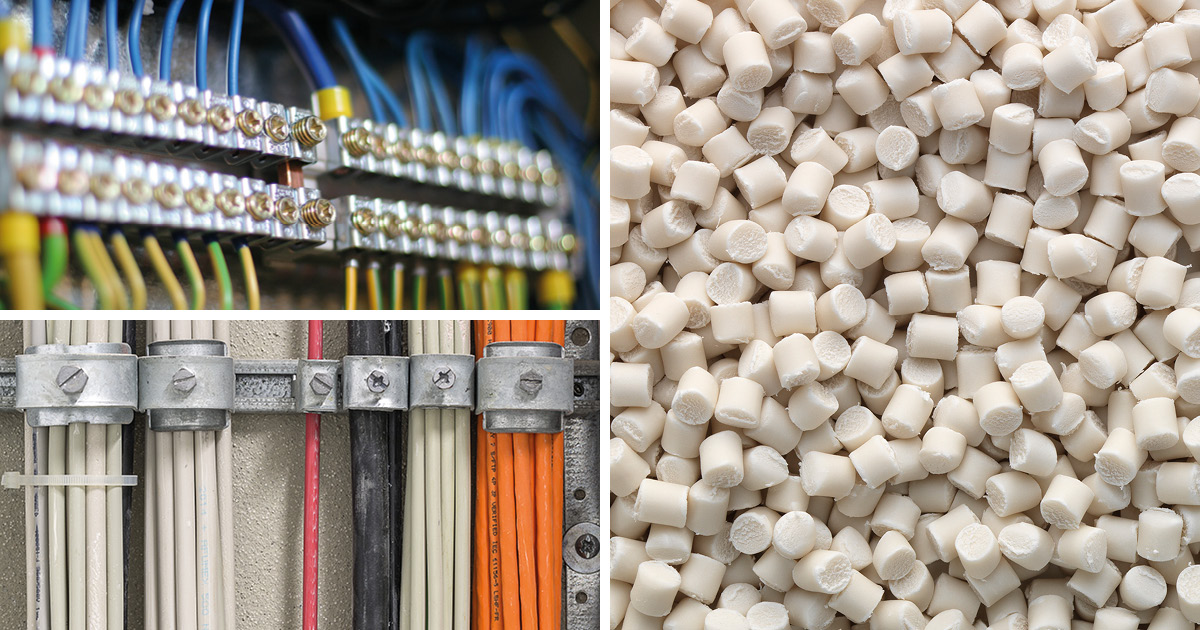

The new state-of-the-art COMPEO compounder is perfect for cable compounds, PVC pelletizing, masterbatch, calender feeding, rubber compounds, performance compounds, engineering plastics, thermoplastic elastomers, thermosets, PBT, PET, bitumen, bioplastics, hot melt, friction coatings …

Das könnte Sie auch interessieren…

COMPEO Special – Saving lives with the right choice of cables!

Which compound might be the most important one during a heat wave? Our answer: HFFR cable compounds!

BUSS in motion – COO Marko Stähler on the machine design of COMPEO

Why is the design of our new compounder generation COMPEO so revolutionary? Find out in the newest installment of our executive video series, where Marko Stähler, COO of BUSS, explains the well thought out concept of COMPEO.

COMPEO Special: State-of-the-art and up-to-date with Bio Plastics

Plastics are everywhere, from furniture to construction, cables to medical devices, paint, pipes, even textiles. The different types of plastics, from common to high-performance, hold many advantages for a broad range of industries and applications.