COMPEO – New configurable process zone

The fully configurable process zone of COMPEO compounders opens up completely new process engineering possibilities through the application of mixing and kneading elements with two to six rows of screw flights. The new geometries make it possible to achieve previously conflicting goals such as a high specific throughput with controllable energy input. In addition, the process window is significantly larger with COMPEO compounding machine. Throughput can be varied in a ratio of 1:6, increasing both system flexibility and user-friendliness.

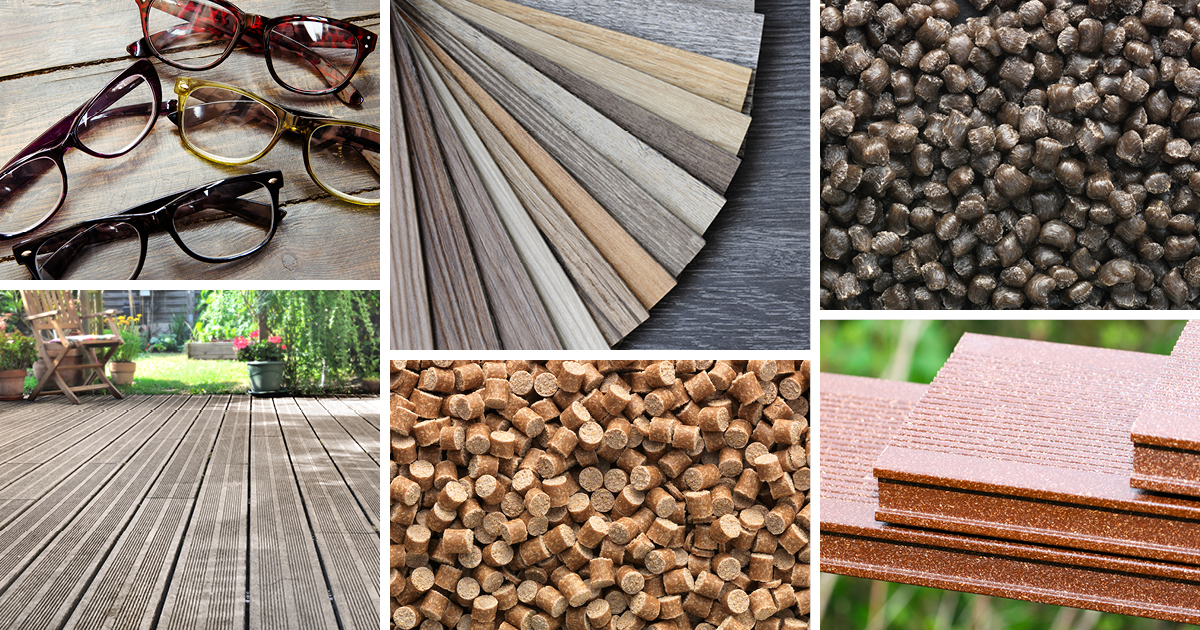

The new state-of-the-art COMPEO compounder is perfect for cable compounds, PVC pelletizing, masterbatch, calender feeding, rubber compounds, performance compounds, engineering plastics, thermoplastic elastomers, thermosets, PBT, PET, bitumen, bioplastics, hot melt, friction coatings …

Das könnte Sie auch interessieren…

Cold winter, hot talks – BUSS at the Interplastica in Moscow

Russia in winter is not for everyone, but our BUSS team is having a great time at the Interplastica in Moscow.

BUSS in motion – CEO Dr. Philip Nising on the company’s journey

Dr. Philip Nising, the CEO of BUSS, looks back at our journey of the last months and years, developing COMPEO, the flagship of BUSS innovation and engineering.

COMPEO special: What’s wood got to do with it?

For thousands of years mankind used wood to build houses, wagons, bridges and ships. Other natural fibers likes flax and hemp were made into ropes, sails and corn sacks. And what exactly does that have to do with compounding?