COMPEO – New configurable process zone

The fully configurable process zone of COMPEO compounders opens up completely new process engineering possibilities through the application of mixing and kneading elements with two to six rows of screw flights. The new geometries make it possible to achieve previously conflicting goals such as a high specific throughput with controllable energy input. In addition, the process window is significantly larger with COMPEO compounding machine. Throughput can be varied in a ratio of 1:6, increasing both system flexibility and user-friendliness.

The new state-of-the-art COMPEO compounder is perfect for cable compounds, PVC pelletizing, masterbatch, calender feeding, rubber compounds, performance compounds, engineering plastics, thermoplastic elastomers, thermosets, PBT, PET, bitumen, bioplastics, hot melt, friction coatings …

Das könnte Sie auch interessieren…

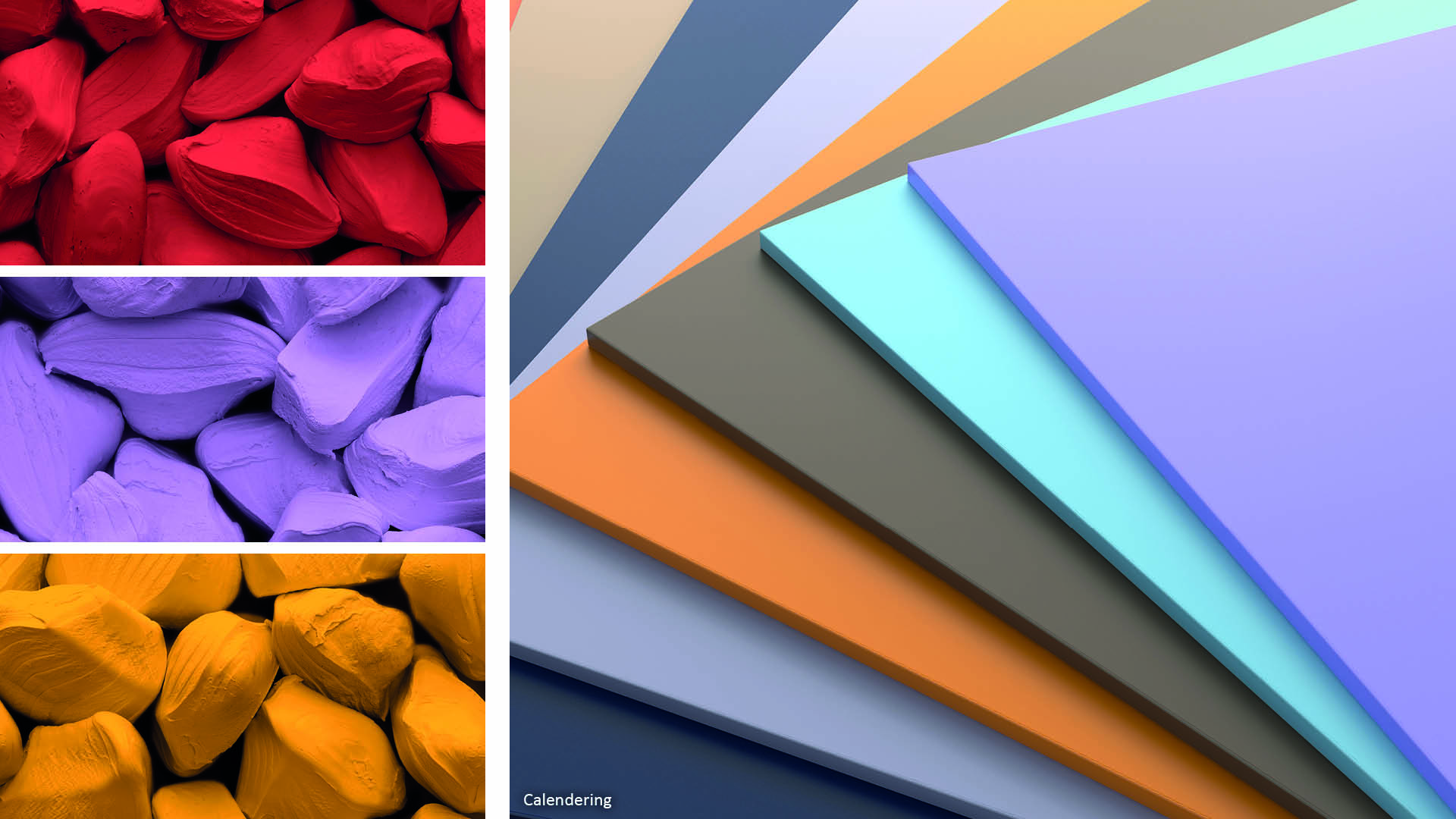

COMPEO Special – Calendering

BUSS has more than 50 years of experience in calender feeding. This makes the BUSS Co-Kneader technology ideal for all kinds of calendering, from PVC materials to rubber, TPU, PE and PET.

Compounding World – A close look at COMPEO

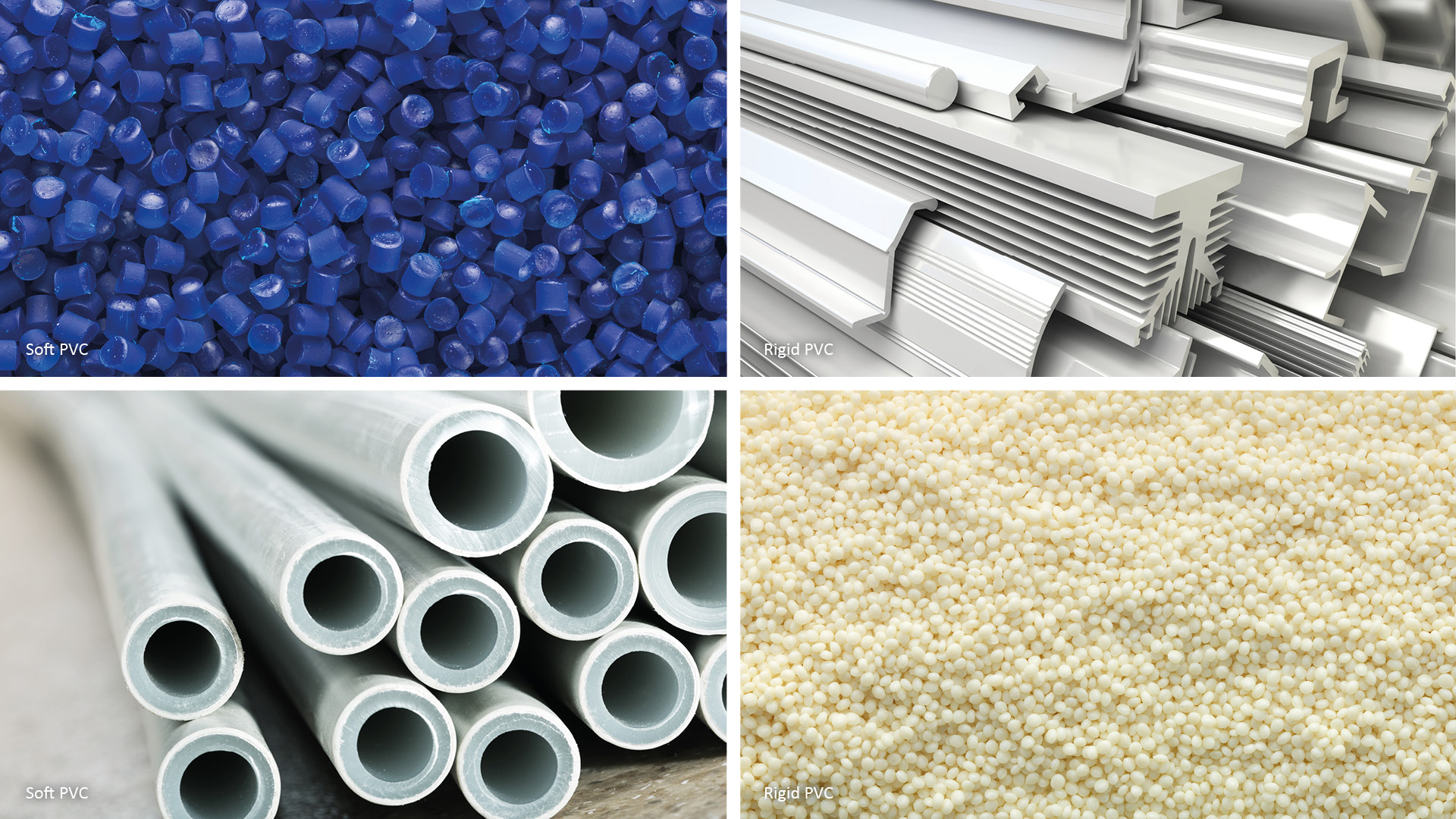

Our new compounding system COMPEO covers the whole spectrum of PVC applications. Thanks to its modular design, the COMPEO series can be precisely configured to meet the specific compounding application.

COMPEO Special – PVC Pelletizing

Our new compounding system COMPEO covers the whole spectrum of PVC applications. Thanks to its modular design, the COMPEO series can be precisely configured to meet the specific compounding application.