COMPEO – New configurable process zone

The fully configurable process zone of COMPEO compounders opens up completely new process engineering possibilities through the application of mixing and kneading elements with two to six rows of screw flights. The new geometries make it possible to achieve previously conflicting goals such as a high specific throughput with controllable energy input. In addition, the process window is significantly larger with COMPEO compounding machine. Throughput can be varied in a ratio of 1:6, increasing both system flexibility and user-friendliness.

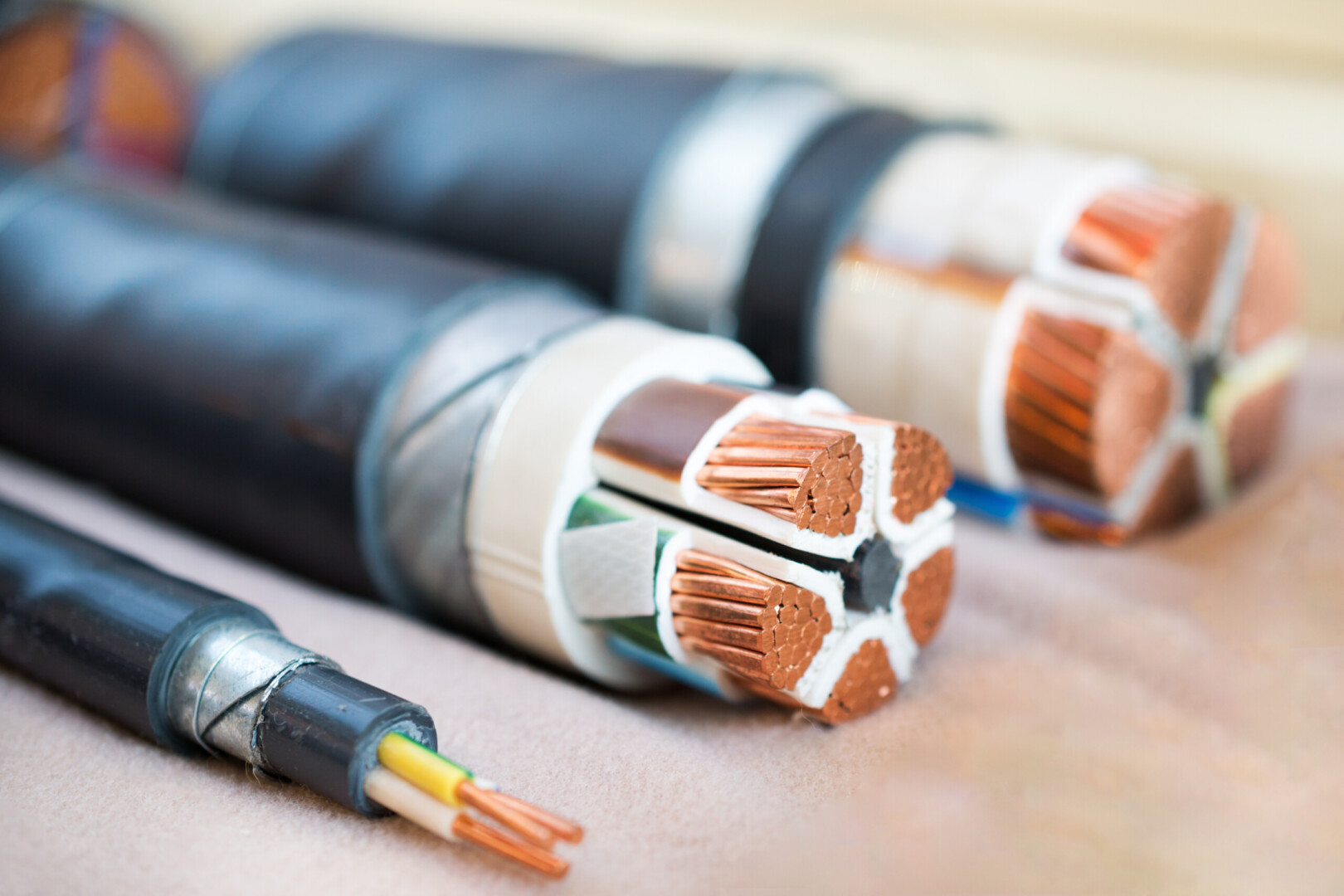

The new state-of-the-art COMPEO compounder is perfect for cable compounds, PVC pelletizing, masterbatch, calender feeding, rubber compounds, performance compounds, engineering plastics, thermoplastic elastomers, thermosets, PBT, PET, bitumen, bioplastics, hot melt, friction coatings …

Das könnte Sie auch interessieren…

COMPEO – Special Cable Compounds

Withstanding the ingress of moisture, extremely good electrical resistance properties and flame retardancy, … The list of requirements for cable compounds is long and depends highly on its end uses.

COMPEO – Innovative control concept

The new COMPEO compounding system is equipped with a touch-screen control system that is based on a state of-the-art control system (Siemens or Allen Bradley) and features an OPC-UA interface for connection to higher-level IT architectures.

COMPEO – A glimpse back and a look ahead

It's half-time on the world premiere tour of our COMPEO compounding system.