COMPEO – New configurable process zone

The fully configurable process zone of COMPEO compounders opens up completely new process engineering possibilities through the application of mixing and kneading elements with two to six rows of screw flights. The new geometries make it possible to achieve previously conflicting goals such as a high specific throughput with controllable energy input. In addition, the process window is significantly larger with COMPEO compounding machine. Throughput can be varied in a ratio of 1:6, increasing both system flexibility and user-friendliness.

The new state-of-the-art COMPEO compounder is perfect for cable compounds, PVC pelletizing, masterbatch, calender feeding, rubber compounds, performance compounds, engineering plastics, thermoplastic elastomers, thermosets, PBT, PET, bitumen, bioplastics, hot melt, friction coatings …

Das könnte Sie auch interessieren…

Time for inspection

Time for inspection: Use the time now, in case not all machines are running at full capacity. By taking measures at the right time, production capability can be guaranteed and plant availability increased to ensure a successful re-start of capacity. The specialists of the BUSS service team are there for you and provide support for inspection and repair.

Production: standstill or resumption? Tips from the BUSS Service Team

Production: standstill or resumption? Tips from the BUSS Service Team. Owing to the current situation, production facilities around the globe are at a standstill. However, little by little, operations will be resumed and we will gradually return to a normal situation.

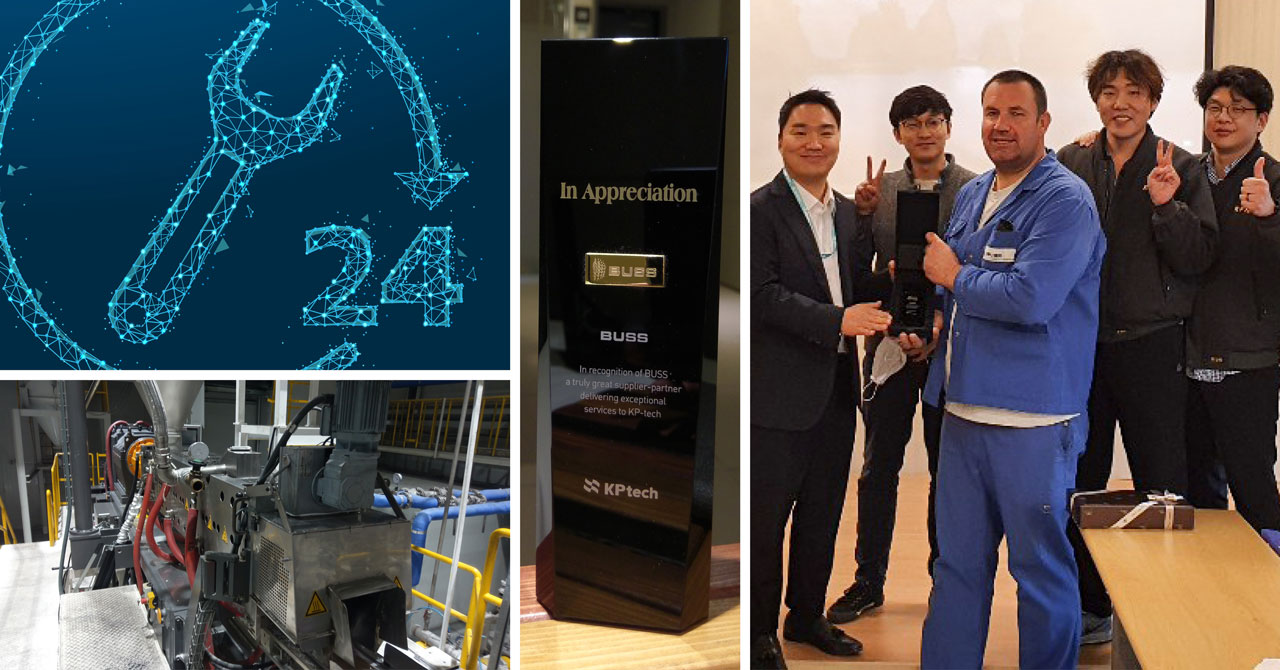

BUSS to the rescue in Korea

Imagine that during these days of nearly worldwide lockdowns, you need acute help for your compounding system … and the BUSS service team is there for you! This was the case as the BUSS service team came to the rescue in Korea for a company that manufactures calendered PVC films for medical packaging, which are urgently needed at the moment.