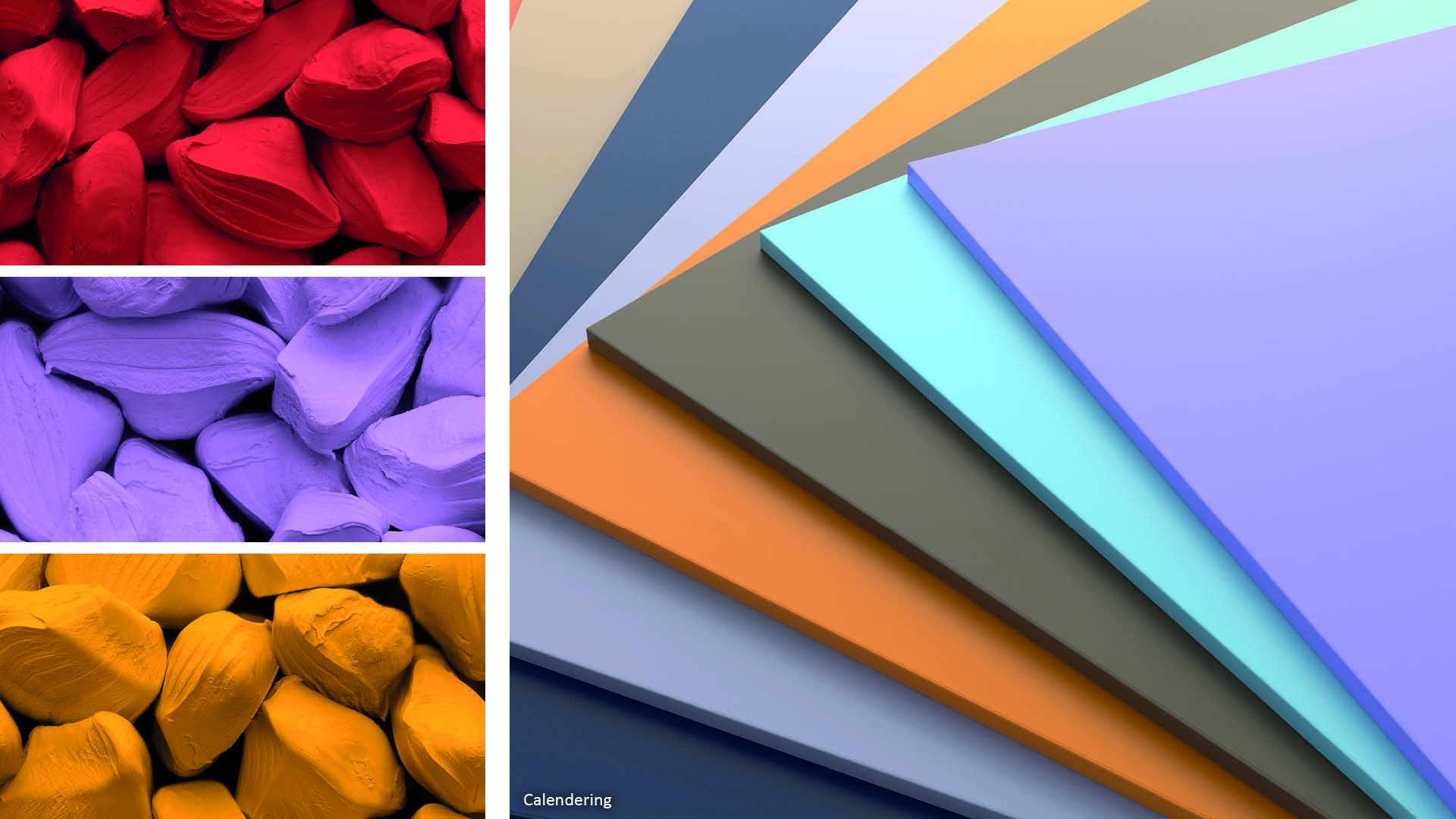

COMPEO Special – Calendering

Calendering – A classical form of direct processing

Calendering is the process of smoothing and compressing a material by passing a continuous sheet through a series of temperature controlled rolls. The process of calendering originates in the paper and textile industries, and can be traced back into the 17th century. The word “calender” is a derivation of the Greek word κύλινδρος (kylindros), which literally means “cylinder”.

In the plastics industry, calendering is used to form film or sheeting and to apply coatings. Calendering is a classical form of direct processing. Raw materials are fed into the BUSS Co-Kneader and compounded. The extrudate from the BUSS Co-Kneader is directly fed to the calender and passed through the calender rollers. The plastic emerges as a flat film or sheet. Thickness, surface finish and texture can be adjusted according to the endproducts requirements. BUSS has more than 50 years of experience in calender feeding. This makes the BUSS Co-Kneader technology ideal for all kinds of calendering, from PVC materials to rubber, TPU, PE and PET.

Das könnte Sie auch interessieren…

COMPEO special: A festival of colours and competence

Only two more days until Holi, the traditional Indian festival of colours, celebrating the arrival of spring and with it, the colours! But there is another event that we are looking for this week: the European Coatings Show in Nuremberg!

COMPEO for the win: “2019 Plastics Industry – Ringier Technology Innovation Award”

Every year, the Ringier Technology Innovation Awards for industrial manufacturing is rewarded to a select group of innovators in China's plastics industry. The eleven award categories include the whole range of the plastics industry, from raw materials and additives, to extrusion molds, components and automation.

BUSS in motion – Head of Process, Dr. François Loviat on BUSS Kneader technology

The success of BUSS can be attributed to our core competence: high quality in process engineering. The unique operating principle is the reason for the excellent mixing capabilities of our Co-Kneaders.