COMPEO Special – Calendering

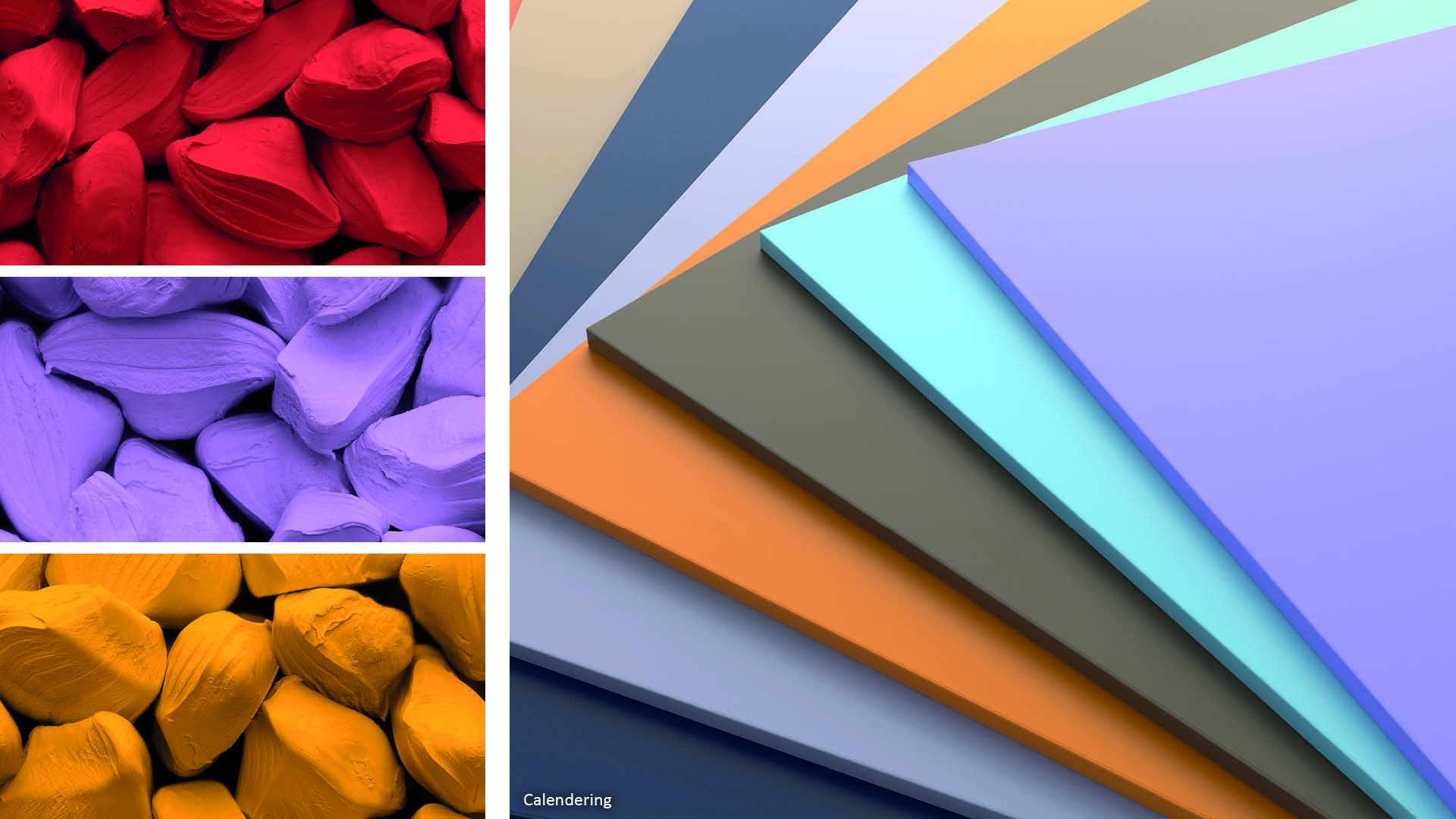

Calendering – A classical form of direct processing

Calendering is the process of smoothing and compressing a material by passing a continuous sheet through a series of temperature controlled rolls. The process of calendering originates in the paper and textile industries, and can be traced back into the 17th century. The word “calender” is a derivation of the Greek word κύλινδρος (kylindros), which literally means “cylinder”.

In the plastics industry, calendering is used to form film or sheeting and to apply coatings. Calendering is a classical form of direct processing. Raw materials are fed into the BUSS Co-Kneader and compounded. The extrudate from the BUSS Co-Kneader is directly fed to the calender and passed through the calender rollers. The plastic emerges as a flat film or sheet. Thickness, surface finish and texture can be adjusted according to the endproducts requirements. BUSS has more than 50 years of experience in calender feeding. This makes the BUSS Co-Kneader technology ideal for all kinds of calendering, from PVC materials to rubber, TPU, PE and PET.

Das könnte Sie auch interessieren…

COMPEO – the efficient allrounder among the compounding systems

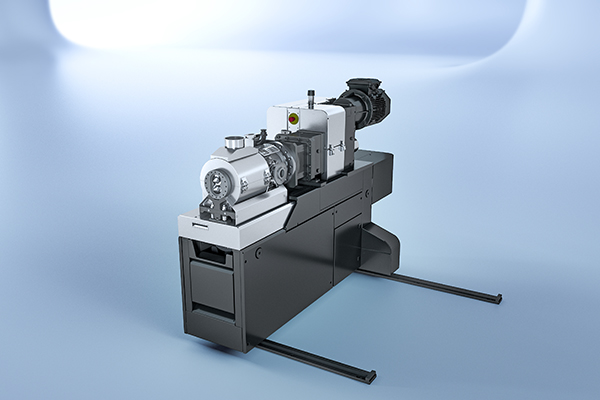

The innovative concept of the new COMPEO compounder system consists of various components. Today we present the next component that ensures maximum compounding efficiency: the new COMPEO discharge concept.

COMPEO – Innovative discharge concept

The new COMPEO discharge unit is based on the principle of a conical twin screw, designed to run in a metered method. The entire controlled pressure build-up takes place in the slowly rotating twin screw.

Start Refurbishment

At BUSS, we’re proud to announce the start of refurbishment works for our machine assembly hall!