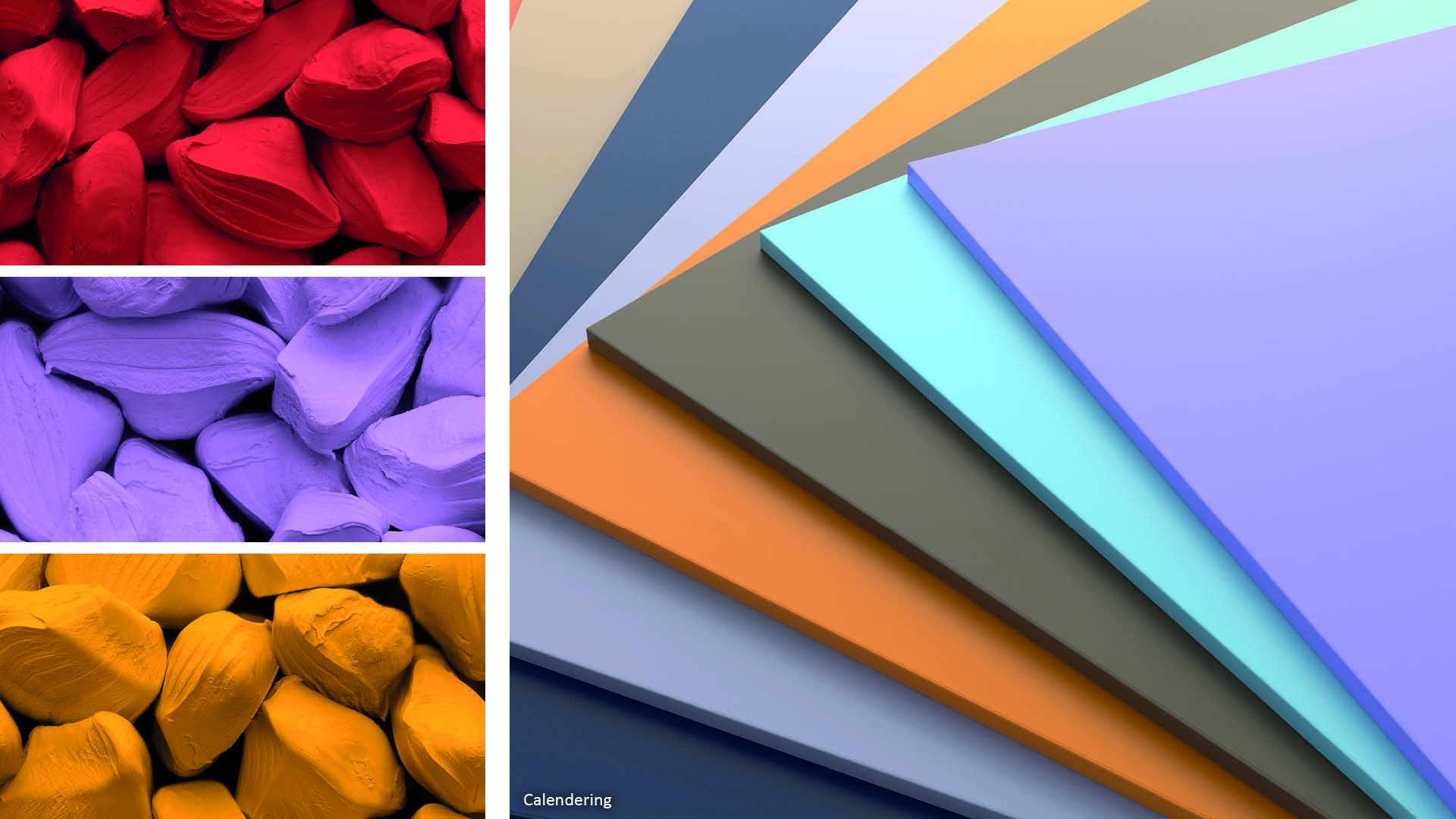

COMPEO Special – Calendering

Calendering – A classical form of direct processing

Calendering is the process of smoothing and compressing a material by passing a continuous sheet through a series of temperature controlled rolls. The process of calendering originates in the paper and textile industries, and can be traced back into the 17th century. The word “calender” is a derivation of the Greek word κύλινδρος (kylindros), which literally means “cylinder”.

In the plastics industry, calendering is used to form film or sheeting and to apply coatings. Calendering is a classical form of direct processing. Raw materials are fed into the BUSS Co-Kneader and compounded. The extrudate from the BUSS Co-Kneader is directly fed to the calender and passed through the calender rollers. The plastic emerges as a flat film or sheet. Thickness, surface finish and texture can be adjusted according to the endproducts requirements. BUSS has more than 50 years of experience in calender feeding. This makes the BUSS Co-Kneader technology ideal for all kinds of calendering, from PVC materials to rubber, TPU, PE and PET.

Das könnte Sie auch interessieren…

PLAST2018 in Milan

Four successful trade fair days in Milan are behind the BUSS team.

COMPEO – New configurable process zone

The fully configurable process zone of COMPEO compounders opens up completely new process engineering possibilities through the application of mixing and kneading elements with two to six rows of screw flights.

BUSS has developed the new COMPEO compounder generation

BUSS has developed the new COMPEO compounder generation to meet current and future plastics industry requirements. With its unique functions, COMPEO offers new, convincing advantages and benefits for a highly varied scope of application.