COMPEO special: How to handle a superhero compound!

Polyamide Compounds

Good durability and tensile strength, high impact, chemical and fire resistance … what sounds like a description of a Marvel superhero is actually a list of requirements for engineering plastics. In some industries, like construction, automotive and industrial applications, plastics are exposed to aggressive chemicals and demanding environments, along with challenging mechanical and thermal requirements. For these use cases, polyamide compounds are the right choice. Some of the polyamide compounds, like the partially aromatic high-performance polyamides, also known as polyphthalamides (PPA), reach heat distortion temperatures of up to 280°C. Using a combination of reinforcing agents, fillers, flame retardants and other additives, polyamide compounds can be highly customized for a broad range of applications. Compounding powerful plastics like polyamides ultimately brings a long list of intricate requirements:

- Specific energy inputs need to be as gentle as possible.

- Large amounts of fillers and flame retardants have to be perfectly distributed.

- Reinforcement fibres must be added so as to optimize mechanical properties.

- All the while, high dwell times in the respective process zones must be maintained.

That is not a trivial task for a standard compounder! Luckily, BUSS has perfected its continuous Kneader technology and created its own superhero with the new compounder generation COMPEO. COMPEO combines performance and robustness in a unique, multifunctional series. The series was developed for all temperature ranges up to 400°C. Given the system’s modular construction and novel process geometries, COMPEO can be used within an extremely diverse application spectrum. Even high performance plastics like polyamides, that come with a superhero-like list of requirements, are no adversary for our COMPEO compounder series.

Das könnte Sie auch interessieren…

Time for inspection

Time for inspection: Use the time now, in case not all machines are running at full capacity. By taking measures at the right time, production capability can be guaranteed and plant availability increased to ensure a successful re-start of capacity. The specialists of the BUSS service team are there for you and provide support for inspection and repair.

Production: standstill or resumption? Tips from the BUSS Service Team

Production: standstill or resumption? Tips from the BUSS Service Team. Owing to the current situation, production facilities around the globe are at a standstill. However, little by little, operations will be resumed and we will gradually return to a normal situation.

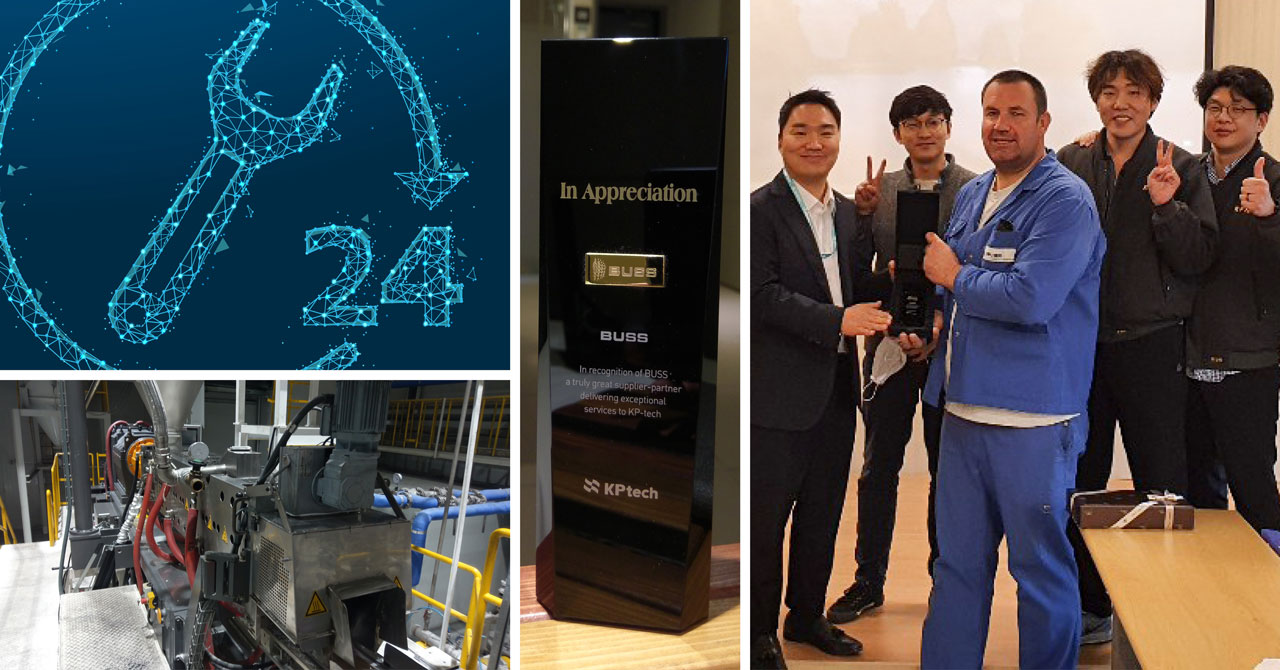

BUSS to the rescue in Korea

Imagine that during these days of nearly worldwide lockdowns, you need acute help for your compounding system … and the BUSS service team is there for you! This was the case as the BUSS service team came to the rescue in Korea for a company that manufactures calendered PVC films for medical packaging, which are urgently needed at the moment.