COMPEO special: What’s wood got to do with it?

Natural Fiber Composites

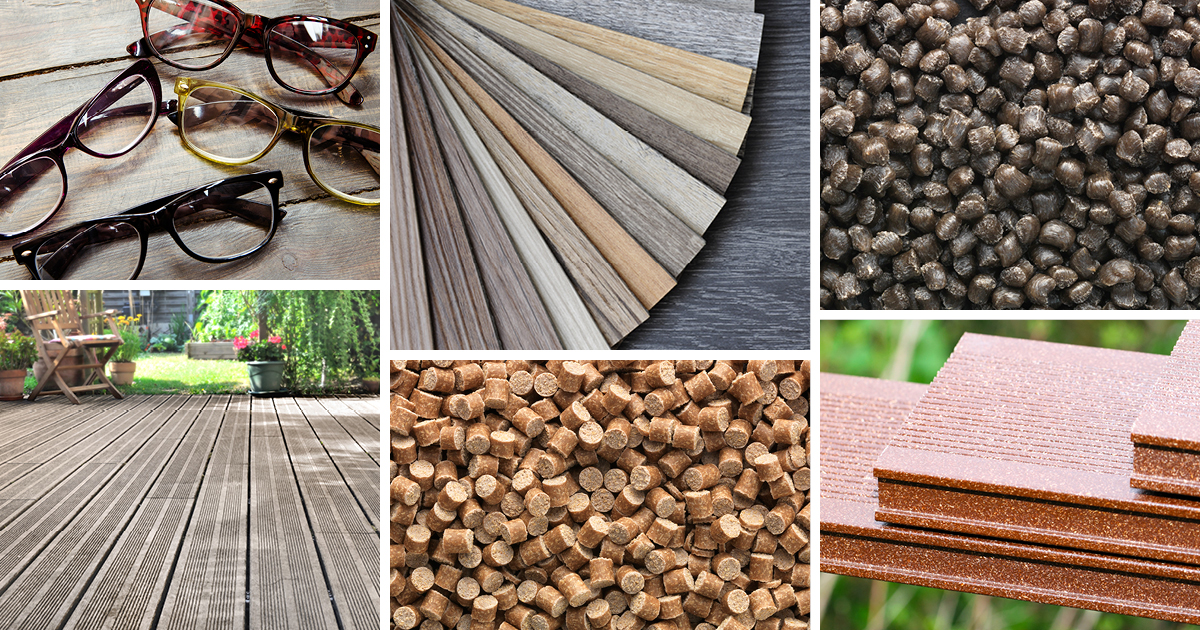

For thousands of years, mankind used wood to build houses, wagons, bridges and ships. Other natural fibers likes flax and hemp were made into ropes, sails and corn sacks. And what exactly does that have to do with compounding? Well, over the last centuries, new applications and technologies have been developed to utilize, process and manipulate these natural fibers. One of those: natural fiber composites. Chemical agents bond natural fibers – everything from flax, hemp, jute, sisal, and cotton, all the way to wood, sawdust and rice husks – with additives into strong composites. These natural fiber composites are elastic and guarantee tensile and impact strength, while still being relatively light in weight. They can be used for various goods, but one of their main application fields are the automotive and aircraft industries. And with that, the circle is complete. What started out with wood wagons ended up in natural fiber composites in the automotive industry.

With more than a hundred years of company history, BUSS knows when to rely on proven concepts, and when to adapt those concepts to current demands. In 2018, we successfully launched our new compounder generation COMPEO that combines longstanding expertise in compounding with innovative engineering. Building on proven concepts, developing them further, making them better, more effective, that is what BUSS stands for. Similar to natural fiber composites, which is only one of many compounding industries that our COMPEO can be tailored to.

Das könnte Sie auch interessieren…

COMPEO – compounding technology for the polymers industry

With COMPEO, the state-of-the-art compounding machine from BUSS, you lay the foundation for reinforced end products which are more scratch-resistant, more flame-retardant, and more weather-resistant — while saving resources.

COMPEO – A unique compounder concept for the polymer industry

The state-of-the-art compounding technology of COMPEO meets the extremely high requirements of the polymer industry: a wide range of applications, a large operating window, high flexibility and robustness, as well as consistent process stability, but also operational and operator safety, energy efficiency and reduced operating costs.

Solution for high-quality 220kV power cables for China

The optimum material composition for high-voltage power cables is still a major issue. Together with P&M Cable Consulting we have developed an individual solution for a Chinese cable manufacturer.