COMPEO Special – Saving lives with the right choice of cables!

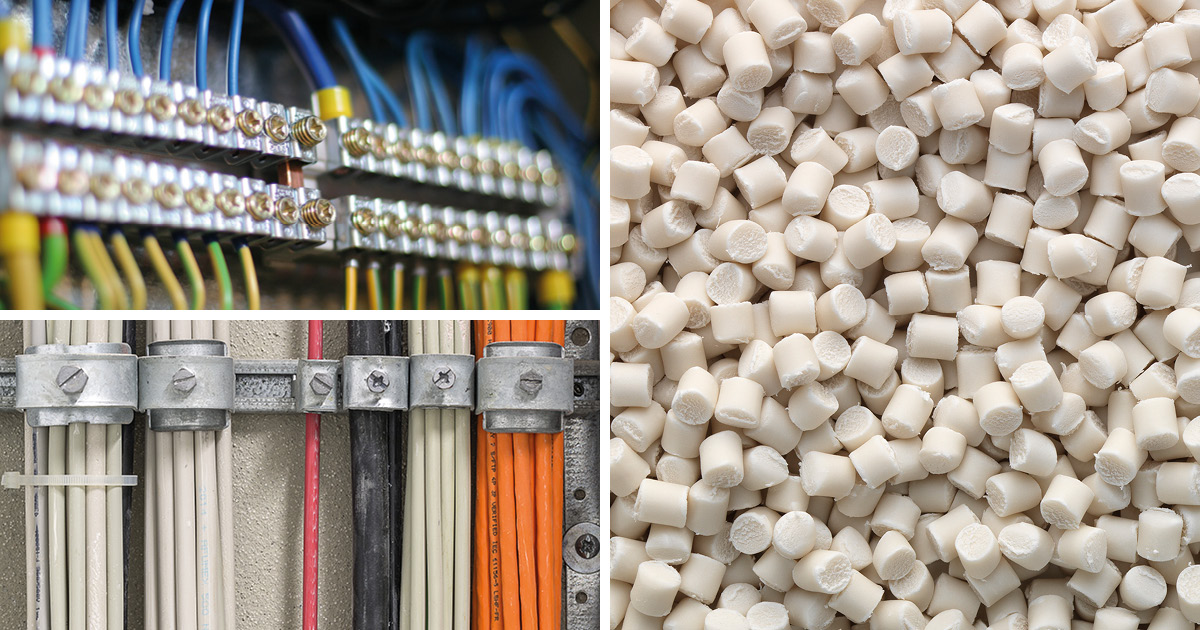

HFFR Cable Compounds

It’s official now: June 2019 was the hottest June ever recorded worldwide. From sunstrokes to wildfires, the hazards of heat waves are manifold. To avoid indoor risks like cable fires, caution is required during heat waves, especially regarding electric appliances. Studies have shown that higher ambient temperatures can lead to reduced transmission capacity of power cables, while the peak electricity load increases simultaneously. That can result in overheating of power cables and therefore also to cable fires. This even applies to underground cable networks up to one meter below surface level where most cables are installed. Imagine your daily electric appliances, like refrigerator or air conditioning, failing in the middle of a heat wave! While that thought is uncomfortable, the possibility of a cable fire in a public place, like the subway or the mall, is straight-up frightening.

Best vs. worst case scenario

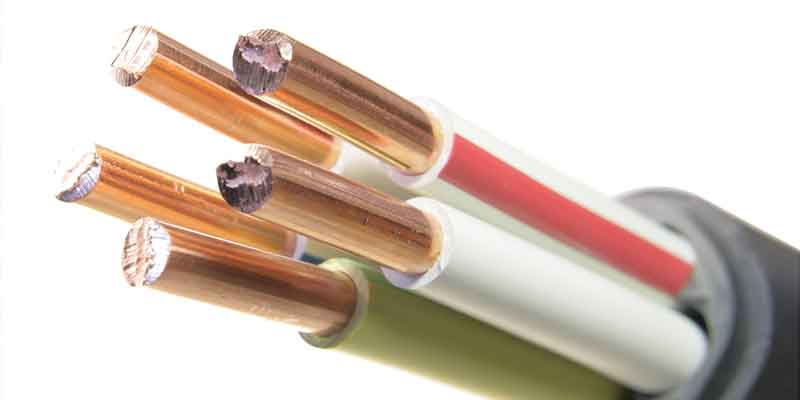

Luckily, there is a way to prevent this: Halogen Free Flame Retardant (HFFR) cables. Long time flame retardant cables were based on halogen, which can be a health hazard in fire situations, as halogen – when burning – produces thick, toxic and corrosive gases. Worst case scenario: the thick fumes impede a quick escape and lead to toxication deaths for the people trapped in enclosed spaces. Best case scenario: the electric wiring is irreparably damaged by the corrosive gases. In any case, halogen free flame retardant cables are the better option. With excellent insulation and flame retardance properties, they are the ideal material for electric wiring cables in all spaces where people live, work and interact daily.

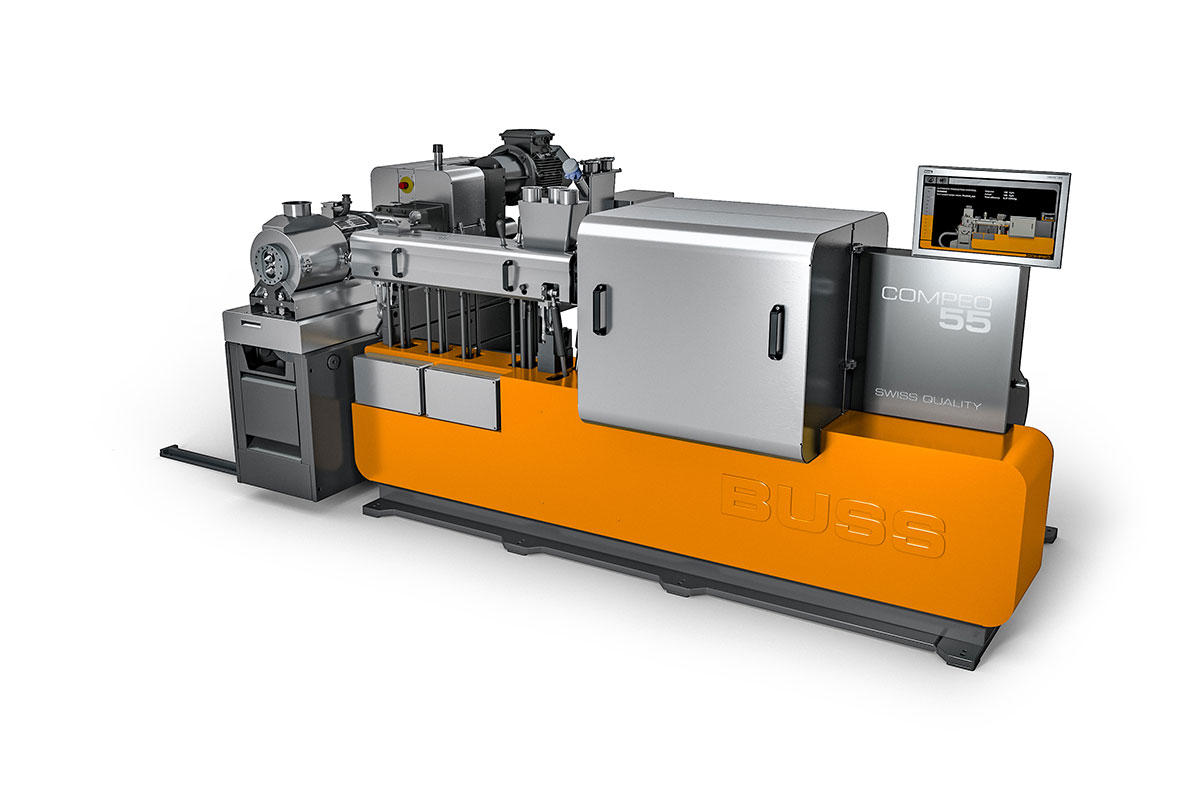

State-of-the-art compounding

To achieve these crucial properties of HFFR cables, flame retardants such as ATH have to be dispersed and distributed extremely well within the compound mix. Equally as important is a stringent temperature control, preventing the flame retardant additives to react during compounding.

Our new compounder generation COMPEO offers a great number of mixing cycles with the highest possible mixing efficiency and product quality, whilst ensuring maximum throughput at moderate and uniform shear rates. More importantly, the liquid injectors can be positioned at almost any points along the process section, so the flame retardants can be added to the mix at the perfect point of time and place. As the entire compounding line is continuously monitored by temperature sensors, we can assure great quality control throughout the whole HFFR compounding process.

High quality compounds

This is why HFFR cable compounds produced on BUSS compounders meet the strict safety standards of the European Construction Products Regulations. To reduce fire risk and to protect people and property is ultimately the purpose of using HFFR cable compounds. We at BUSS are happy to contribute to this. Afterall, the summer has just begun and the next heat wave might be just around the corner!

Read more about HFFR cable compounding at BUSS here: https://busscorp.com/industries/cable-compounds/hffr-cable-compounds/

Das könnte Sie auch interessieren…

COMPEO special: A festival of colours and competence

Only two more days until Holi, the traditional Indian festival of colours, celebrating the arrival of spring and with it, the colours! But there is another event that we are looking for this week: the European Coatings Show in Nuremberg!

COMPEO for the win: “2019 Plastics Industry – Ringier Technology Innovation Award”

Every year, the Ringier Technology Innovation Awards for industrial manufacturing is rewarded to a select group of innovators in China's plastics industry. The eleven award categories include the whole range of the plastics industry, from raw materials and additives, to extrusion molds, components and automation.

BUSS in motion – Head of Process, Dr. François Loviat on BUSS Kneader technology

The success of BUSS can be attributed to our core competence: high quality in process engineering. The unique operating principle is the reason for the excellent mixing capabilities of our Co-Kneaders.