COMPEO Special: State-of-the-art and up-to-date with Bio Plastics

Bio Plastics

Plastics are everywhere, from furniture to construction, cables to medical devices, paint, pipes, even textiles. The different types of plastics, from common to high-performance, hold many advantages for a broad range of industries and applications. Over the years, these industries change and evolve. One example is the packaging industry, especially in the food sector. With rising oil prices and changing environmental awareness in the 1980s, bioplastics made a comeback. They have been pushed out of the market at the beginning of the 20th century, when plastics production based on crude oil was discovered and proved to be much cheaper.

Bioplastics can be degraded by naturally occurring microorganisms to water and CO2. That makes them wholly unsuitable for many industries, and very fitting for a few. Nowadays, food packaging as well as other consumer durables are made more and more from bioplastics based on cellulose.

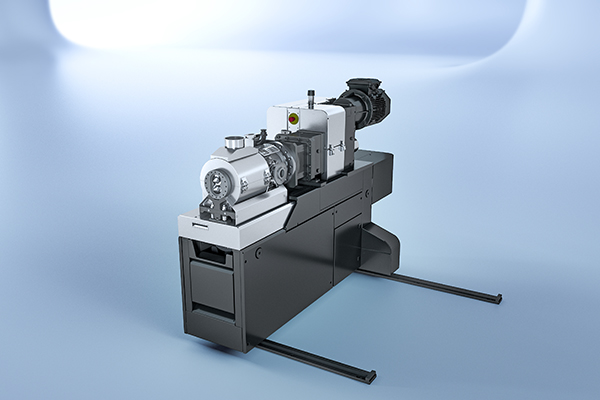

BUSS aspires to be state-of-the-art, as well as up-to-date. We accomplished this with our new compounder generation COMPEO!

Bioplastics compounding is just one example of the many applications, to which COMPEO can be modelled to. With bio plastics compounding, the careful incorporation of fibres, fillers and additives is a key element, as it often requires multiple metering of dry ingredient streams as well as the injection of liquid additives at defined positions in the compounder. Thanks to COMPEO`s modular design, this can be easily achieved.

Read more about bio plastics compounding here: https://busscorp.com/industries/bioplastics/

Das könnte Sie auch interessieren…

COMPEO – the efficient allrounder among the compounding systems

The innovative concept of the new COMPEO compounder system consists of various components. Today we present the next component that ensures maximum compounding efficiency: the new COMPEO discharge concept.

COMPEO – Innovative discharge concept

The new COMPEO discharge unit is based on the principle of a conical twin screw, designed to run in a metered method. The entire controlled pressure build-up takes place in the slowly rotating twin screw.

Start Refurbishment

At BUSS, we’re proud to announce the start of refurbishment works for our machine assembly hall!