Services in China

Two years ago we opened our Chinese branch office in Songjiang, a district in the southwest of Shanghai. The aim was to be closer to our Chinese and Asian customers with our comprehensive service offering. It makes regular maintenance work easier. And, if worst comes to worst, repairs can be carried out much faster to keep downtimes of the machine or entire system as short as possible. Two years on, the service business is well-established and continues to pick up speed.

Efficient und professional – two current examples

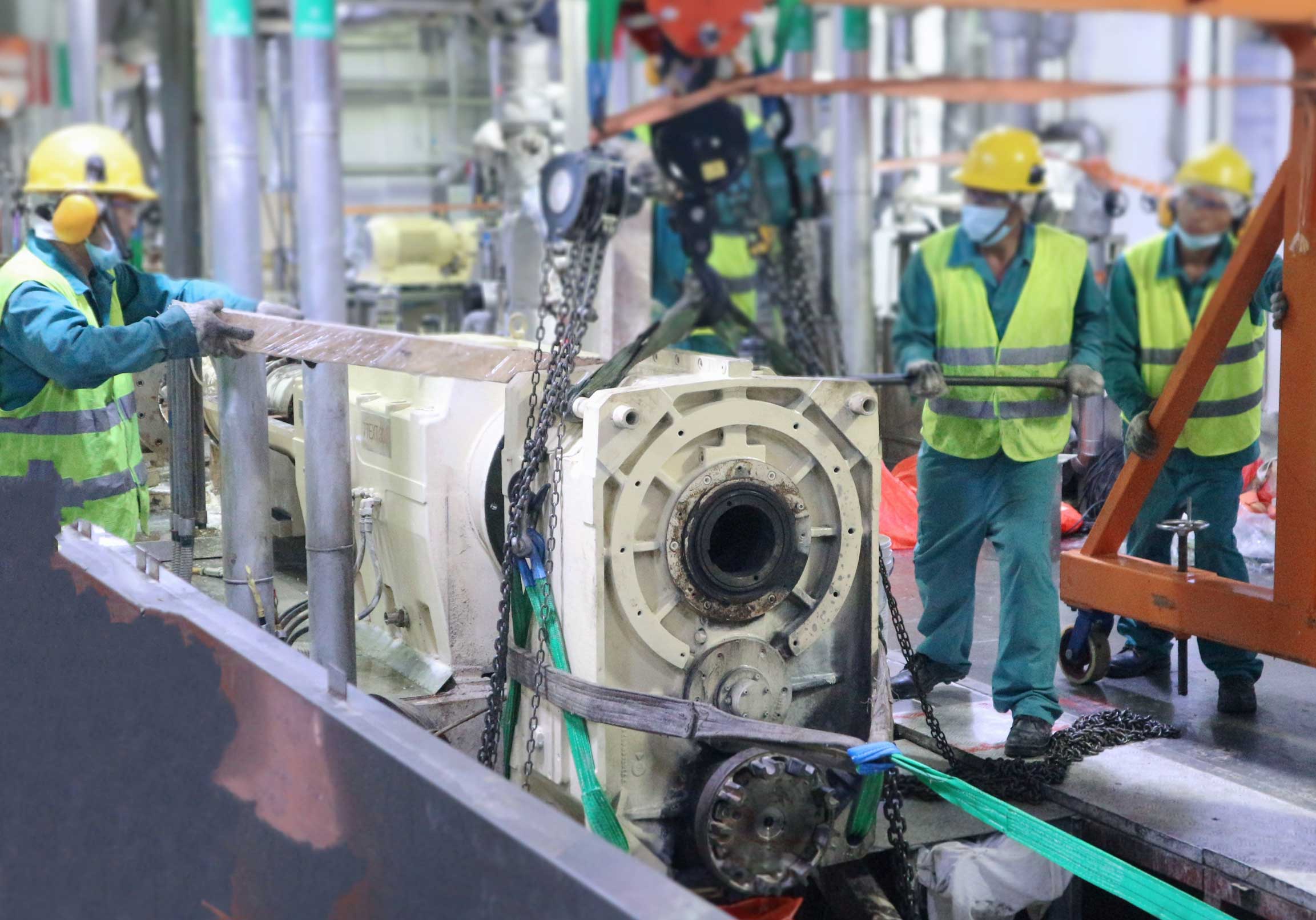

Recently, BUSS Shanghai engineers completed the repair and maintenance of a carbon black masterbatch R&D lab machine’s gearbox for a world-renowned carbon black masterbatch manufacturer in our Songjiang workshop (see photo). From the on-site disassembly of the gearbox to the on-site installation and start-up after maintenance, the service quality, professional skills, and service attitude of BUSS Shanghai’s engineers were commended by our customer.

Not long ago, Buss Shanghai replaced the gearbox of an important large BUSS extruder for one of the largest chewing gum manufacturers in China. The customer was very busy in production, and in the end, our Shanghai colleagues successfully completed the gearbox replacement within a limited time window as scheduled. The old gearbox will be repaired and maintained in the BUSS Songjiang workshops later. We received favourable comments from our client on the services we provided, including spare parts ordering, delivery, and coordination for replacement, and also including preparation, on-site disassembly, and installation guidance.

Range of services locally available in China

Our range of services in China focuses on preventive maintenance to improve the productivity and availability of our customers’ equipment throughout its life cycle. The major scope of service is as follows:

- According to the customer’s annual spare parts requirements, stock up in our spare parts warehouse, and settle in batches as needed

- Short delivery times for standard spare and wear parts

- Regularly conduct preventive inspections and corresponding maintenance for customers’ equipment

- Overhaul and maintenance after the gearboxes reach a certain operating time

- Train users on equipment maintenance, operation, troubleshooting, and process technology

- On-site troubleshooting and debottlenecking

- Equipment modification and upgrading

A dedicated team for the success of our customers

The BUSS team in Shanghai, which numbers 8 people so far, is very committed. The common focus is on the success of the customer. It is all about making sure that our customers achieve their goals. In order to ensure this, BUSS compounders are kept running smoothly. In every situation, the BUSS team in China is committed to this aim.

Das könnte Sie auch interessieren…

COMPEO special: A festival of colours and competence

Only two more days until Holi, the traditional Indian festival of colours, celebrating the arrival of spring and with it, the colours! But there is another event that we are looking for this week: the European Coatings Show in Nuremberg!

COMPEO for the win: “2019 Plastics Industry – Ringier Technology Innovation Award”

Every year, the Ringier Technology Innovation Awards for industrial manufacturing is rewarded to a select group of innovators in China's plastics industry. The eleven award categories include the whole range of the plastics industry, from raw materials and additives, to extrusion molds, components and automation.

BUSS in motion – Head of Process, Dr. François Loviat on BUSS Kneader technology

The success of BUSS can be attributed to our core competence: high quality in process engineering. The unique operating principle is the reason for the excellent mixing capabilities of our Co-Kneaders.