Fridays for Future: sustainability in the plastics industry!

Every Friday, students all over the world demonstrate against climate change and for more sustainability. It’s a topic that affects all aspects of life and business. From grocery shopping without plastic bags to CO2 compensation for flights. From electric vehicles to renewable energies. Sustainability is not just a trend anymore, it’s a value, and more importantly, it’s a global demand.

The plastics industry is deeply affected by this trend as well. While pessimists see the obstacles here, optimists spot the opportunities. New and innovative solutions are needed. Business concepts are changing from mass production to recycling. Compounds like Bioplastics, which used to be niche products, are now in high demand. Highly specialized performance and engineering compounds like FRTP or Polycarbonate are utilized as replacement for metal components in automotive construction. They weigh less than metal, and lighter cars consume less fuel, hence sustainability. The plastics industry is adapting, changing, evolving.

Bioplastics are either bio-based, biodegradable or both. Read more here!

Fillers optimize the compound material properties. More about FRTP here!

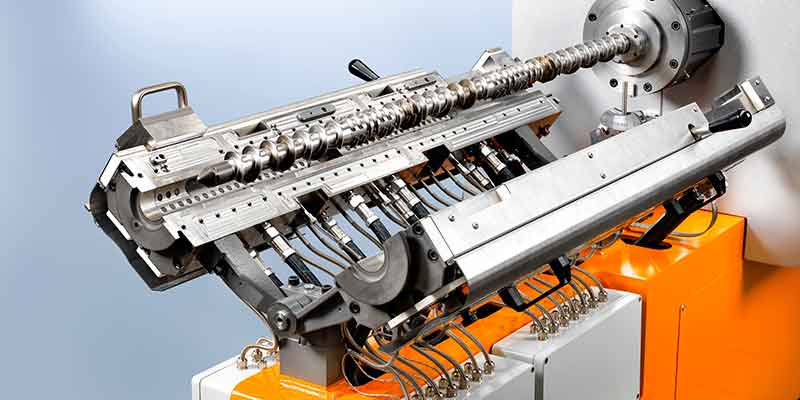

Over the last 70 years, BUSS has always moved with the times. Afterall, change is the only constant. Our new compounder generation COMPEO is proof of this. Three years ago, when we started developing the COMPEO, we realized that the demand for highly specialized compounds will constantly increase. While the quality standards for these compounds are very high, the amount and variety of additives make them expensive. The state-of-the-art technology of COMPEO allows efficient use of additives through controlled and thorough mixing at 15-30 % lower overall specific energy input. The energy for melting and mixing is provided almost entirely mechanically. Thanks to its modular machine design, the COMPEO compounder is highly flexible for a wide range of applications, like Bioplastics, Natural Fiber Compounds or FRTP. BUSS is ready for the coming changes and we are happy to contribute to a more sustainable future thanks to our efficient compounding technology.

You can find more information about COMPEO here.

Das könnte Sie auch interessieren…

Time for inspection

Time for inspection: Use the time now, in case not all machines are running at full capacity. By taking measures at the right time, production capability can be guaranteed and plant availability increased to ensure a successful re-start of capacity. The specialists of the BUSS service team are there for you and provide support for inspection and repair.

Production: standstill or resumption? Tips from the BUSS Service Team

Production: standstill or resumption? Tips from the BUSS Service Team. Owing to the current situation, production facilities around the globe are at a standstill. However, little by little, operations will be resumed and we will gradually return to a normal situation.

BUSS to the rescue in Korea

Imagine that during these days of nearly worldwide lockdowns, you need acute help for your compounding system … and the BUSS service team is there for you! This was the case as the BUSS service team came to the rescue in Korea for a company that manufactures calendered PVC films for medical packaging, which are urgently needed at the moment.