Project Successes In China

BUSS has demonstrated its expertise in the demanding production of HV-XLPE cable insulation materials (cross-linked polyethylene for high voltage): the company has successfully completed projects with Chinese customers from State Grid Corporation of China (the world’s largest energy supply company), Wanhua, Wanma, and Dewei.

Cutting-edge Technology For The Cable Industry

This application places extremely high demands on the quality, purity, and performance of the materials and the systems used. With its kneading technology, BUSS has extensive experience in processing temperature-sensitive materials. This takes place at moderate and uniform shearing speeds.

Thanks to these uniform and moderate shear rates, a temperature below 200 °C can be maintained over the entire length of the process without the temperature peaks that occur in other systems. This reduces the degradation of the materials, which impairs the electrical properties of the end product.

All these customers know that BUSS supplies the best possible compounding technology for their application. Added to this is the local, competent service that these customers trust BUSS for the long term and have been able to successfully complete these projects.

Learn More

Typical plant layout for XLPE insulation material

Links

Das könnte Sie auch interessieren…

Cold winter, hot talks – BUSS at the Interplastica in Moscow

Russia in winter is not for everyone, but our BUSS team is having a great time at the Interplastica in Moscow.

BUSS in motion – CEO Dr. Philip Nising on the company’s journey

Dr. Philip Nising, the CEO of BUSS, looks back at our journey of the last months and years, developing COMPEO, the flagship of BUSS innovation and engineering.

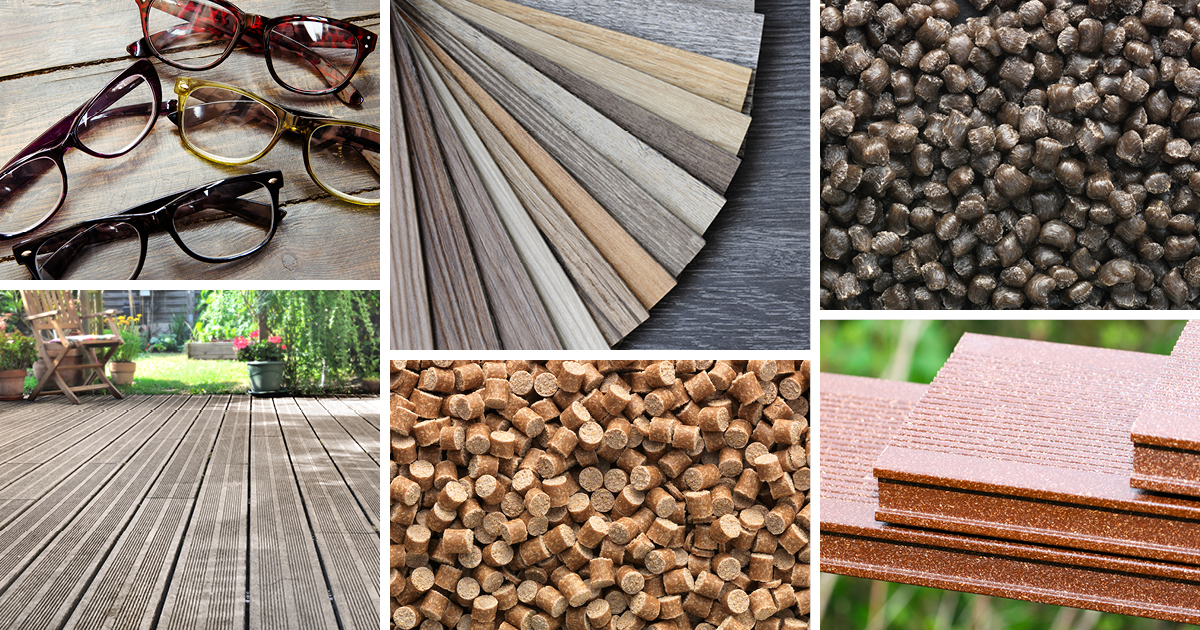

COMPEO special: What’s wood got to do with it?

For thousands of years mankind used wood to build houses, wagons, bridges and ships. Other natural fibers likes flax and hemp were made into ropes, sails and corn sacks. And what exactly does that have to do with compounding?