75 years of BUSS Kneader technology

At BUSS we are happy to celebrate a special anniversary this year. 75 years ago, on August 20, 1945 to be precise, patent applications were filed for the BUSS Kneader technology. The inventor of this technology for continuous compounding of plastics, Heinz List, is still considered a pioneer of process technology today. BUSS history is closely linked to List, for it was here that he brought the technology to market maturity and developed it further during 20 years as technical director. To this day, BUSS compounding systems operate according to the continuous Kneader principle.

Read more about the special features of the BUSS Kneader technology, about gentle compounding with high mixing efficiency and about the good scalability of the continuous Kneader in the compounding process in the detailed technical article published in the “Kunststoffe” magazine by Carl Hanser Verlag, Munich, in October 2020. The authors give insight into the process technology and its advantages. They explain how compounding technology has developed over the decades, its special status in the plastics industry today as an allrounder and as the first choice for demanding compounding tasks. And they give an outlook on how the BUSS Kneader technology will develop in the future in the context of ever more specific requirements.

Learn more about BUSS Kneader technology in this technical paper.

(Reading time is about 10 minutes).

We publish with permission of Carl Hanser Verlag, Munich.

Das könnte Sie auch interessieren…

COMPEO – A glimpse back and a look ahead

It's half-time on the world premiere tour of our COMPEO compounding system.

COMPEO – the efficient allrounder among the compounding systems

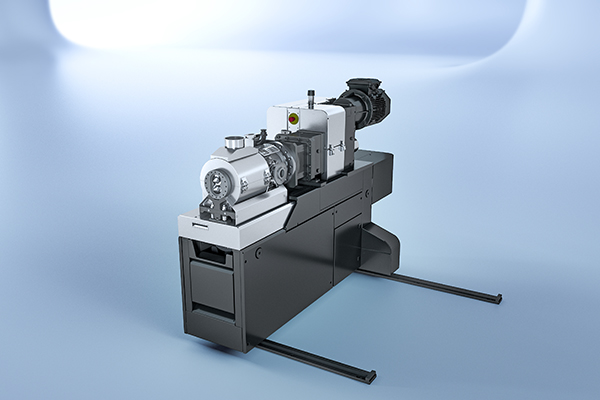

The innovative concept of the new COMPEO compounder system consists of various components. Today we present the next component that ensures maximum compounding efficiency: the new COMPEO discharge concept.

COMPEO – Innovative discharge concept

The new COMPEO discharge unit is based on the principle of a conical twin screw, designed to run in a metered method. The entire controlled pressure build-up takes place in the slowly rotating twin screw.