COMPEO – first choice for reactive extrusion

The Polieco Group, market-leading manufacturer of compounds and adhesives for steel pipe coating, tie-layers for multilayer structures (high-barrier food packaging, PEX/Al pipes) and of structured double-wall high-density polyethylene (HDPE) corrugated pipes, is making a future-proof investment in a COMPEO compounding line. The BUSS compounding extruder will lead to an increase of productivity and to the development of new, innovative products.

The advantages of the COMPEO series, both over predecessor models and other technologies, were impressively demonstrated at the BUSS Campus: gentle mixing of the ingredients of the formulation, precise temperature control at high temperatures and controllable residence time proved to be essential for this reactive extrusion process.

In addition, the expertise of the process team involved has contributed significantly to the relationship of trust that has developed between Polieco and BUSS. The COMPEO 110 will be delivered to the Industrie Polieco – MPB Srl plant in Italy as early as June 2021.

Das könnte Sie auch interessieren…

Buss AG、中国新子会社を正式開業

Buss AGは、カレンダー供給の混練に関して50年以上の実績があります。こうした経験を基に、ブッスの混練技術は、ポリ塩化ビニル(PVC)からゴム、TPU、ポリエチレン、ポリエチレンテレフタレート(PET)まで、あらゆる素材のカレンダー供給に理想的なシステムとなっています。

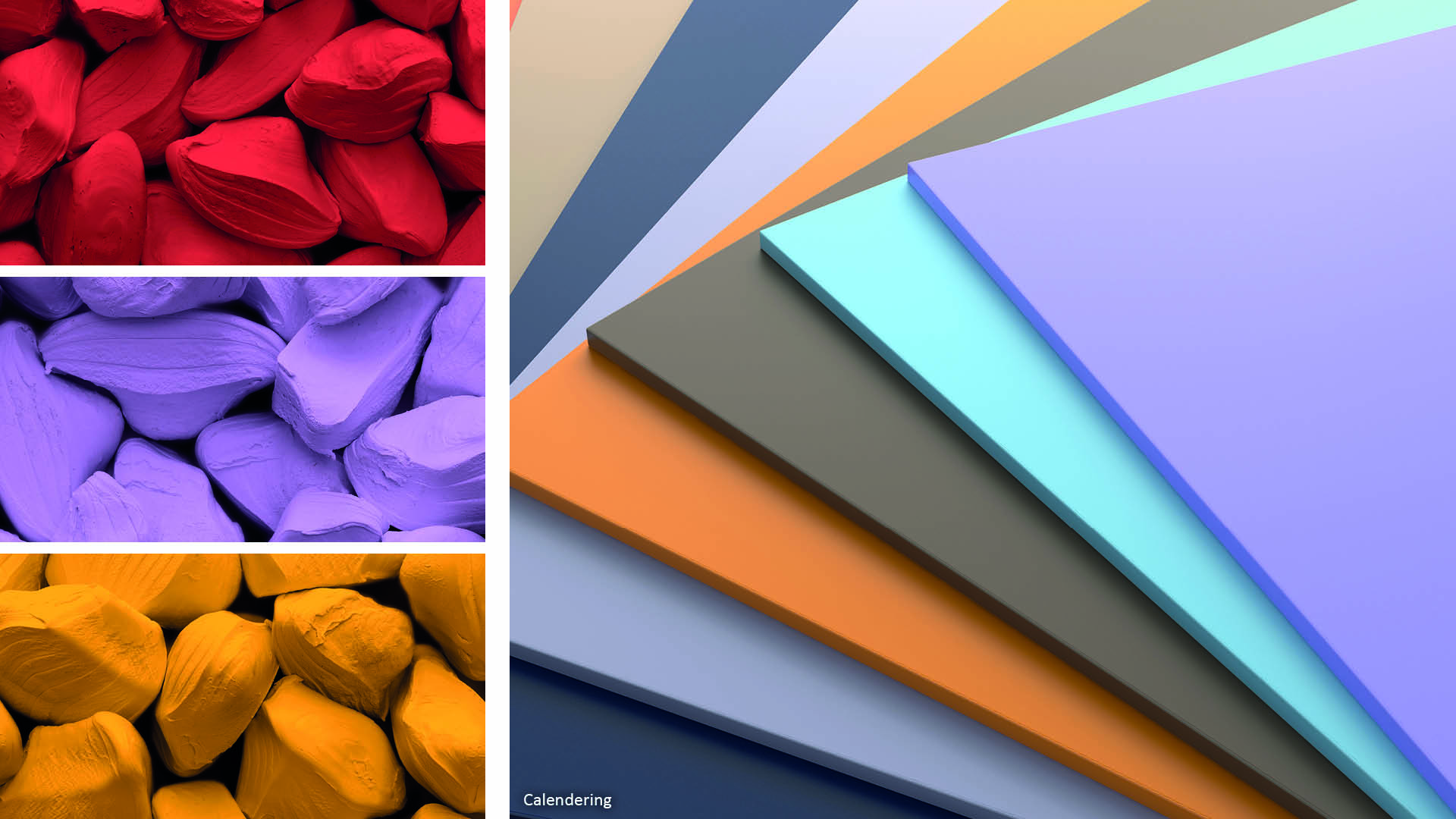

COMPEO Special – Calendering

BUSS has more than 50 years of experience in calender feeding. This makes the BUSS Kneader technology ideal for all kinds of calendering, from PVC materials to rubber, TPU, PE and PET.

Compounding World – A close look at COMPEO

Our new compounding system COMPEO covers the whole spectrum of PVC applications. Thanks to its modular design, the COMPEO series can be precisely configured to meet the specific compounding application.