COMPEO – first choice for reactive extrusion

The Polieco Group, market-leading manufacturer of compounds and adhesives for steel pipe coating, tie-layers for multilayer structures (high-barrier food packaging, PEX/Al pipes) and of structured double-wall high-density polyethylene (HDPE) corrugated pipes, is making a future-proof investment in a COMPEO compounding line. The BUSS compounding extruder will lead to an increase of productivity and to the development of new, innovative products.

The advantages of the COMPEO series, both over predecessor models and other technologies, were impressively demonstrated at the BUSS Campus: gentle mixing of the ingredients of the formulation, precise temperature control at high temperatures and controllable residence time proved to be essential for this reactive extrusion process.

In addition, the expertise of the process team involved has contributed significantly to the relationship of trust that has developed between Polieco and BUSS. The COMPEO 110 will be delivered to the Industrie Polieco – MPB Srl plant in Italy as early as June 2021.

Das könnte Sie auch interessieren…

Solution for high-quality 220kV power cables for China

The optimum material composition for high-voltage power cables is still a major issue. Together with P&M Cable Consulting we have developed an individual solution for a Chinese cable manufacturer.

PLAST2018 in Milan

Four successful trade fair days in Milan are behind the BUSS team.

COMPEO – New configurable process zone

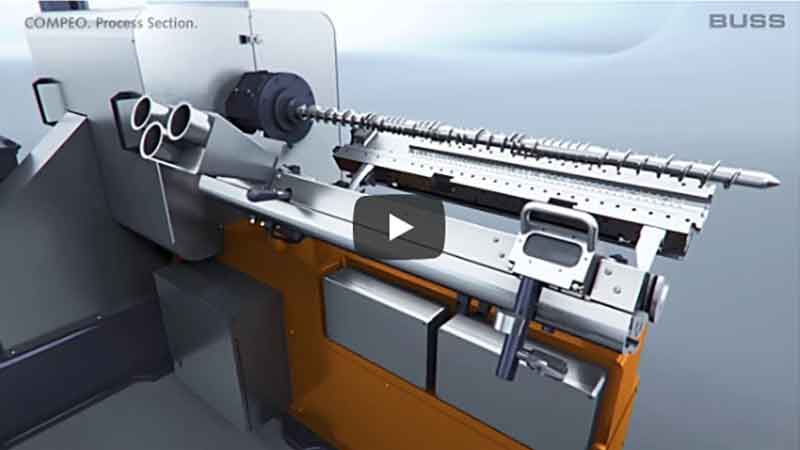

The fully configurable process zone of COMPEO compounders opens up completely new process engineering possibilities through the application of mixing and kneading elements with two to six rows of screw flights.