COMPEO – first choice for reactive extrusion

The Polieco Group, market-leading manufacturer of compounds and adhesives for steel pipe coating, tie-layers for multilayer structures (high-barrier food packaging, PEX/Al pipes) and of structured double-wall high-density polyethylene (HDPE) corrugated pipes, is making a future-proof investment in a COMPEO compounding line. The BUSS compounding extruder will lead to an increase of productivity and to the development of new, innovative products.

The advantages of the COMPEO series, both over predecessor models and other technologies, were impressively demonstrated at the BUSS Campus: gentle mixing of the ingredients of the formulation, precise temperature control at high temperatures and controllable residence time proved to be essential for this reactive extrusion process.

In addition, the expertise of the process team involved has contributed significantly to the relationship of trust that has developed between Polieco and BUSS. The COMPEO 110 will be delivered to the Industrie Polieco – MPB Srl plant in Italy as early as June 2021.

Das könnte Sie auch interessieren…

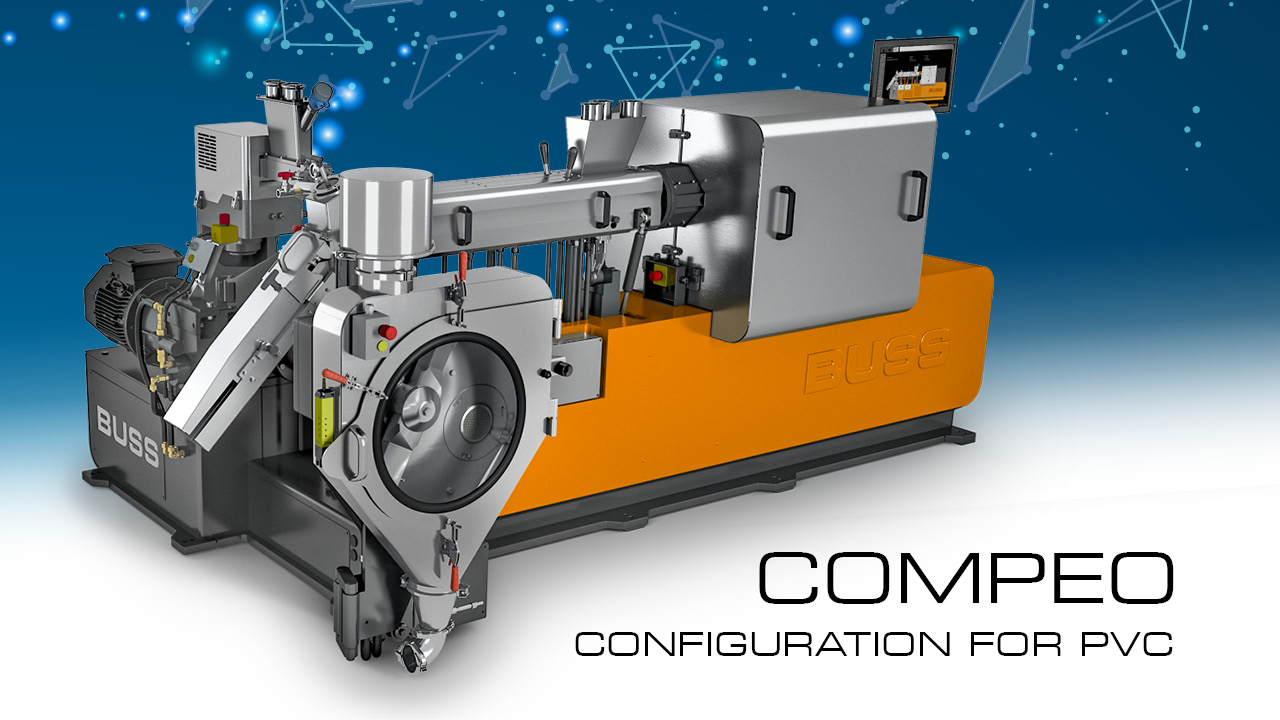

Flexible is better: new COMPEO configuration for PVC processing

Modular is the key: BUSS proudly presents the new cascade-type COMPEO configuration for the processing of sensitive PVC. Highly safe, highly efficient, highly operator-friendly ...

Cooperation with Reifenhäuser India

BUSS was able to win a strong cooperation partner for sales and distribution with Reifenhäuser India Marketing PVT Ltd. (RIMPL). As from June 1, 2020 Reifenhäuser India is supporting ...

New compounder generation COMPEO: award-winning

On July 2, Ringier Industrial Media hosted the "2020 Rubber and Plastic Innovative Materials Application and Processing Technology Summit Forum" held in Shanghai. After winning the Ringier Technology Innovation Award in 2012 and 2019 ...