COMPEO – first choice for reactive extrusion

The Polieco Group, market-leading manufacturer of compounds and adhesives for steel pipe coating, tie-layers for multilayer structures (high-barrier food packaging, PEX/Al pipes) and of structured double-wall high-density polyethylene (HDPE) corrugated pipes, is making a future-proof investment in a COMPEO compounding line. The BUSS compounding extruder will lead to an increase of productivity and to the development of new, innovative products.

The advantages of the COMPEO series, both over predecessor models and other technologies, were impressively demonstrated at the BUSS Campus: gentle mixing of the ingredients of the formulation, precise temperature control at high temperatures and controllable residence time proved to be essential for this reactive extrusion process.

In addition, the expertise of the process team involved has contributed significantly to the relationship of trust that has developed between Polieco and BUSS. The COMPEO 110 will be delivered to the Industrie Polieco – MPB Srl plant in Italy as early as June 2021.

Das könnte Sie auch interessieren…

Time for inspection

Time for inspection: Use the time now, in case not all machines are running at full capacity. By taking measures at the right time, production capability can be guaranteed and plant availability increased to ensure a successful re-start of capacity. The specialists of the BUSS service team are there for you and provide support for inspection and repair.

Fridays for Future: sustainability in the plastics industry!

The second China International Import Expo (CIIE) in Shanghai has just ended. This exhibition aims actively to open the Chinese market to the world. Countries and regions all over the world are invited to strengthen international trade and economic globalization. BUSS participated at the first CIIE in 2018, shortly after the Shanghai team moved into the new office premises.

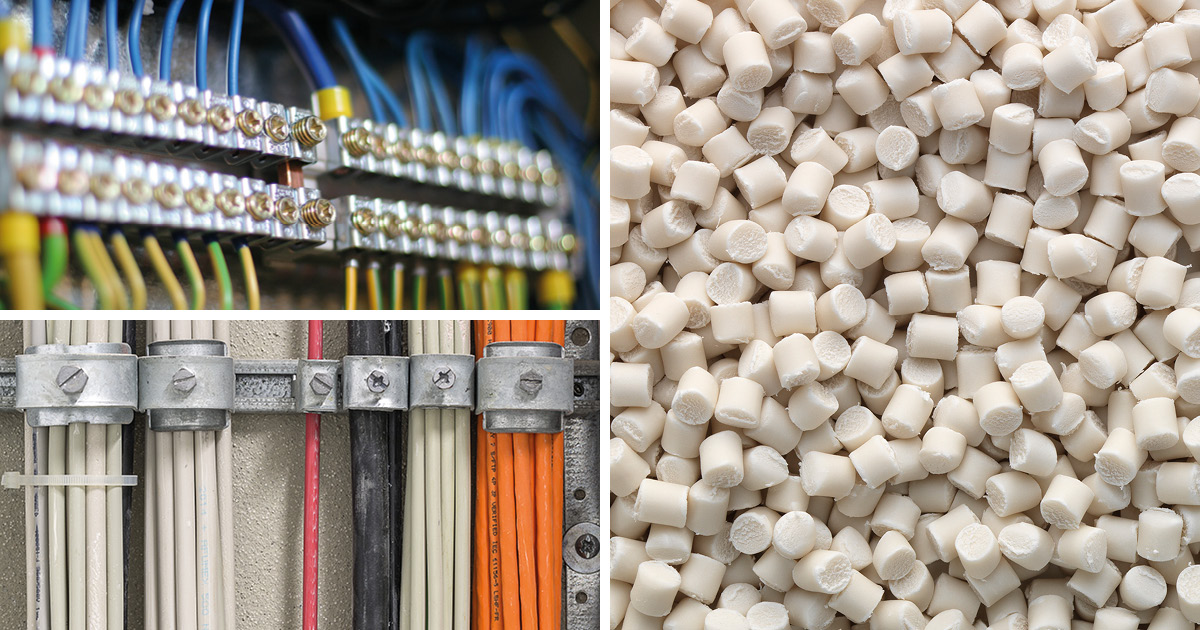

COMPEO Special – Saving lives with the right choice of cables!

Which compound might be the most important one during a heat wave? Our answer: HFFR cable compounds!