COMPEO – Innovative control concept

Industry 4.0 and connectivity are not just buzz words, but the gateway to the future. That is why our new COMPEO compounding system is equipped with a touch-screen control system that is based on a state of-the-art control system (Siemens or Allen Bradley) and features an OPC-UA interface for connection to higher-level IT architectures. The modular control software is structured according to the system configuration and ensures intuitive operation. All essential system parameters such as filling levels, flow rates or quantities, pressures, temperatures and outputs are visualized, recorded, and archived. The control system works with stored formulation parameter sets, which makes it possible to switch between formulations with the push of a button.

The new state-of-the-art COMPEO compounder in combination with this extremely the innovative control unit is particularly suitable for PVC pelletizing, masterbatch, calendering, cable and rubber compounds, performance compounds, engineering plastics, thermoplastic elastomers, thermosets, PBT, PET, bitumen, bioplastics, hot melt, friction coatings …

Das könnte Sie auch interessieren…

COMPEO – A glimpse back and a look ahead

It's half-time on the world premiere tour of our COMPEO compounding system.

COMPEO – the efficient allrounder among the compounding systems

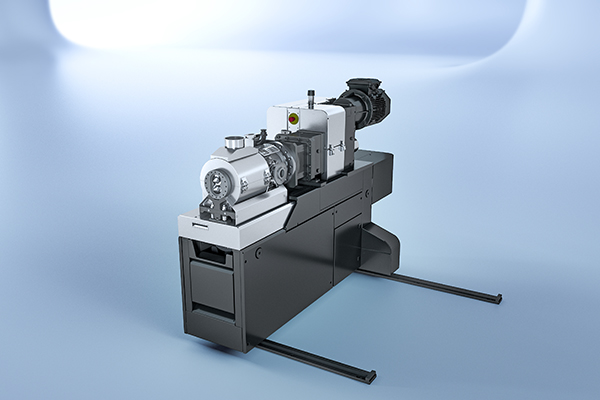

The innovative concept of the new COMPEO compounder system consists of various components. Today we present the next component that ensures maximum compounding efficiency: the new COMPEO discharge concept.

COMPEO – Innovative discharge concept

The new COMPEO discharge unit is based on the principle of a conical twin screw, designed to run in a metered method. The entire controlled pressure build-up takes place in the slowly rotating twin screw.