COMPEO – Innovative control concept

Industry 4.0 and connectivity are not just buzz words, but the gateway to the future. That is why our new COMPEO compounding system is equipped with a touch-screen control system that is based on a state of-the-art control system (Siemens or Allen Bradley) and features an OPC-UA interface for connection to higher-level IT architectures. The modular control software is structured according to the system configuration and ensures intuitive operation. All essential system parameters such as filling levels, flow rates or quantities, pressures, temperatures and outputs are visualized, recorded, and archived. The control system works with stored formulation parameter sets, which makes it possible to switch between formulations with the push of a button.

The new state-of-the-art COMPEO compounder in combination with this extremely the innovative control unit is particularly suitable for PVC pelletizing, masterbatch, calendering, cable and rubber compounds, performance compounds, engineering plastics, thermoplastic elastomers, thermosets, PBT, PET, bitumen, bioplastics, hot melt, friction coatings …

Das könnte Sie auch interessieren…

Solution for high-quality 220kV power cables for China

The optimum material composition for high-voltage power cables is still a major issue. Together with P&M Cable Consulting we have developed an individual solution for a Chinese cable manufacturer.

PLAST2018 in Milan

Four successful trade fair days in Milan are behind the BUSS team.

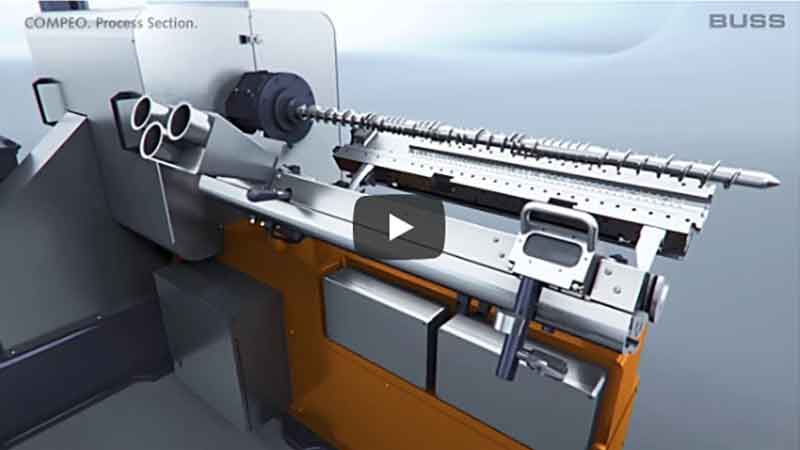

COMPEO – New configurable process zone

The fully configurable process zone of COMPEO compounders opens up completely new process engineering possibilities through the application of mixing and kneading elements with two to six rows of screw flights.