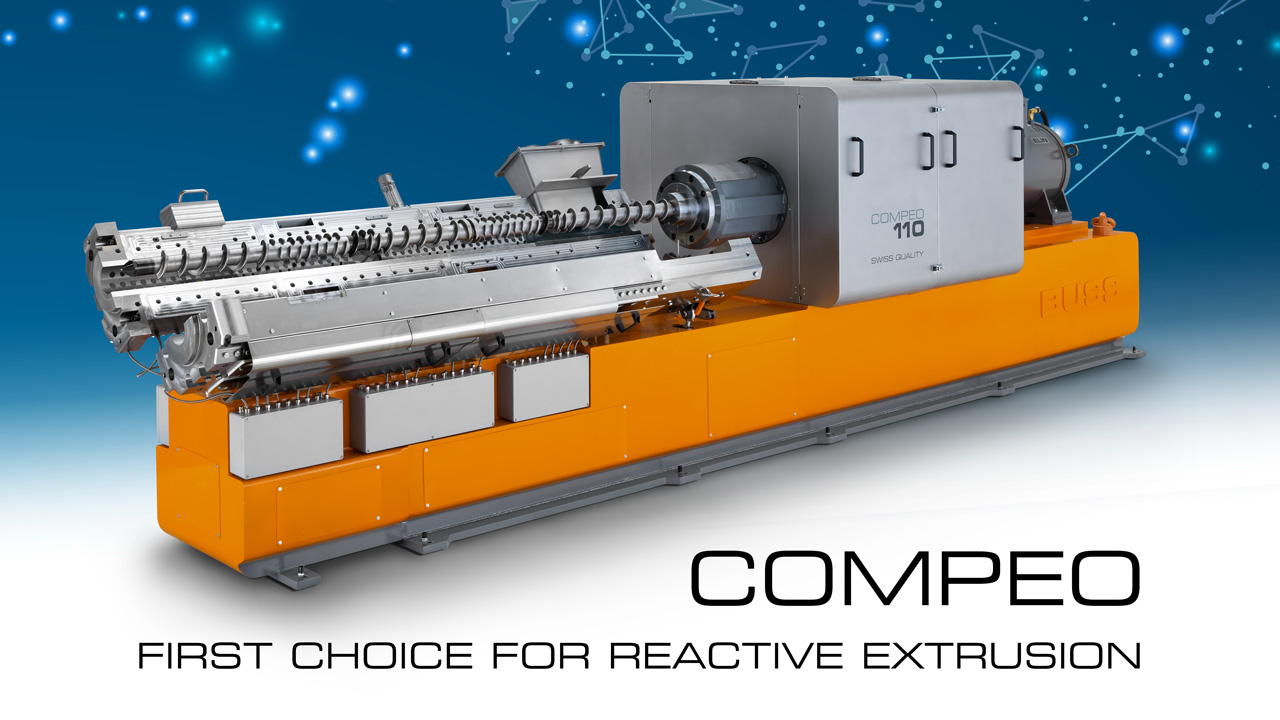

COMPEO – New configurable process zone

The fully configurable process zone of COMPEO compounders opens up completely new process engineering possibilities through the application of mixing and kneading elements with two to six rows of screw flights. The new geometries make it possible to achieve previously conflicting goals such as a high specific throughput with controllable energy input. In addition, the process window is significantly larger with COMPEO compounding machine. Throughput can be varied in a ratio of 1:6, increasing both system flexibility and user-friendliness.

The new state-of-the-art COMPEO compounder is perfect for cable compounds, PVC pelletizing, masterbatch, calender feeding, rubber compounds, performance compounds, engineering plastics, thermoplastic elastomers, thermosets, PBT, PET, bitumen, bioplastics, hot melt, friction coatings …

Das könnte Sie auch interessieren…

From empiricism to systematic interpretation

For 75 years, Buss Kneaders have excelled in the compounding of highly filled and shear-sensitive plastics, especially with stringent mixing requirements. Determination of the optimum process ...

Women in Manufacturing … Of course!

Far too few women still apply for positions in mechanical engineering companies, including ours. Yet it's a great pleasure to work in a technically oriented company ...

COMPEO – first choice for reactive extrusion

The Polieco Group, market-leading manufacturer of compounds and adhesives for steel pipe coating, tie-layers for multilayer structures and of structured double-wall high-density polyethylene corrugated pipes, is making a future-proof investment in a COMPEO compounding line. The BUSS compounding extruder will lead to an increase ...