Compounding World – A close look at COMPEO

COMPEO – The right choice for demanding compounding requirements

Increasing demand for end products with improved properties is driving polymer development towards higher strength, improved scratch resistance, improved flame retardancy, better UV resistance, less weight and more resource saving.

As the tuning of compounds properties through polymer chemistry is already widely exploited, further improvement of those properties has to be increasingly achieved by mixing in more and more sophisticated, sensitive and expensive additives. This is where intensive mixing of sensitive ingredients supersedes the requirement for ever higher throughputs. This kind of reliable mixing and precise control of the temperature profile are traditional strengths of BUSS kneader technology.

In the latest issue of Compounding World magazine, Mark Holmes discusses compounding options, and takes a close look on our new COMPEO series!

Read the full article with interviews and statements of our technology experts here.

Das könnte Sie auch interessieren…

From empiricism to systematic interpretation

For 75 years, Buss Kneaders have excelled in the compounding of highly filled and shear-sensitive plastics, especially with stringent mixing requirements. Determination of the optimum process ...

Women in Manufacturing … Of course!

Far too few women still apply for positions in mechanical engineering companies, including ours. Yet it's a great pleasure to work in a technically oriented company ...

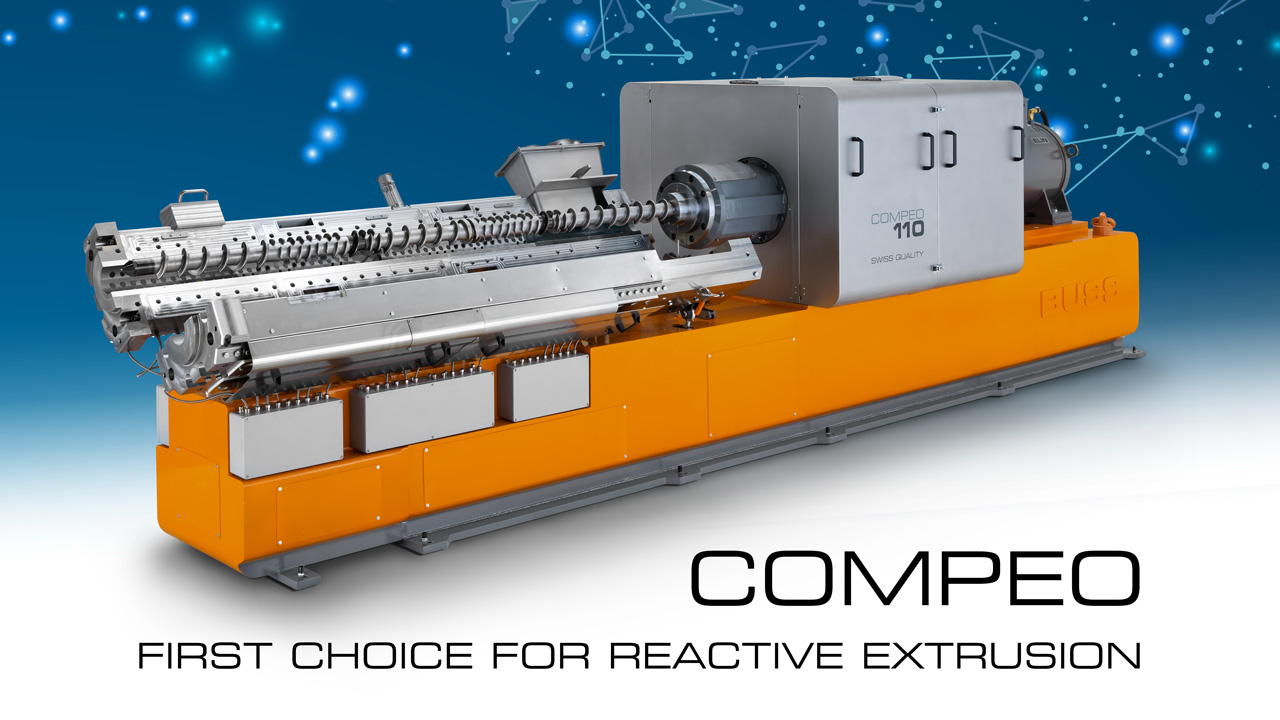

COMPEO – first choice for reactive extrusion

The Polieco Group, market-leading manufacturer of compounds and adhesives for steel pipe coating, tie-layers for multilayer structures and of structured double-wall high-density polyethylene corrugated pipes, is making a future-proof investment in a COMPEO compounding line. The BUSS compounding extruder will lead to an increase ...